- 22 -

8. C-Base Assembly

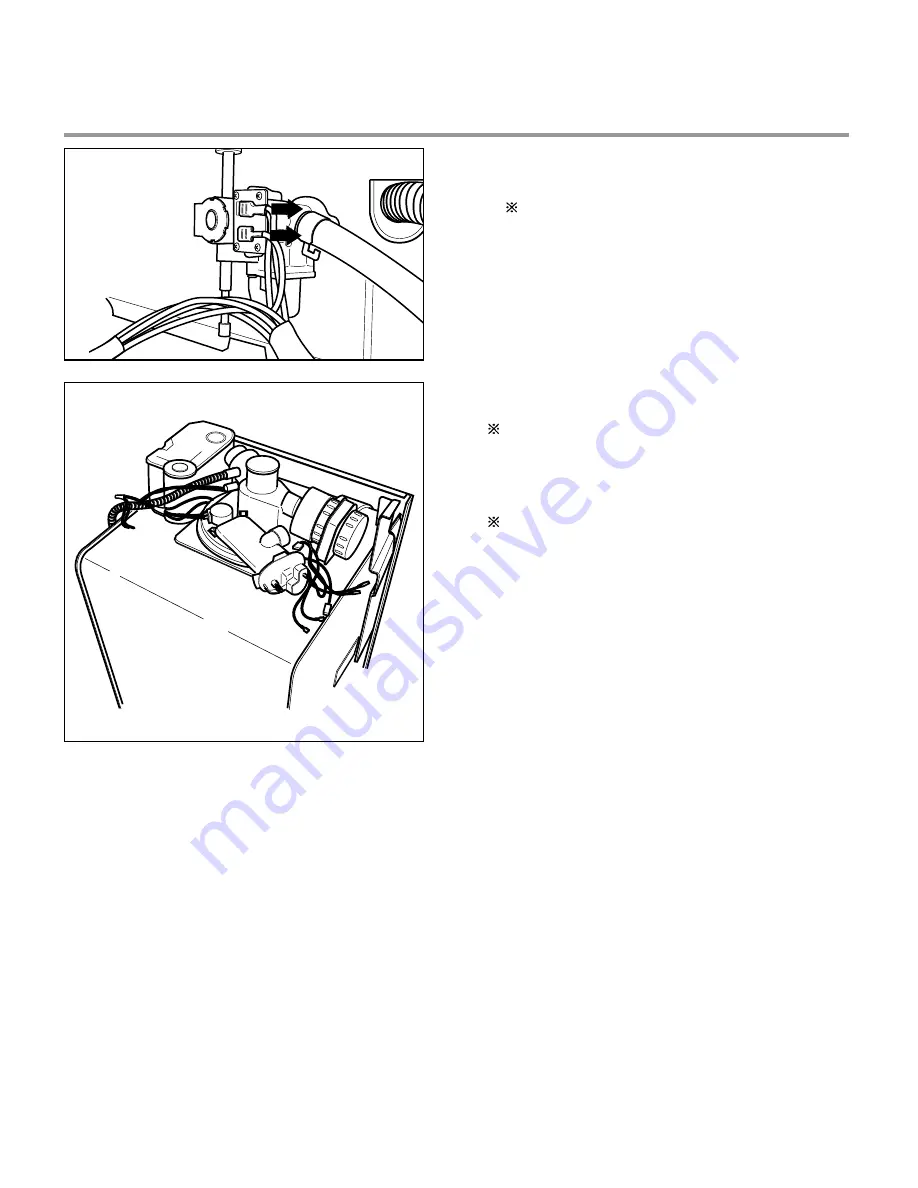

You can repair the parts in the C-Base like

heater case, washing pump, drain motor

etc. you may refer to 7-1. 10. 2)~10)

(Page 20~24)

Don’t disassemble sump by 7-2.

If you want to disassemble the sump, follow

7-1.

4) Disconnect wire from the inlet valve or

Aquastop

Now, you can remove the base from the

tub perfectly.