LGETH -180704-054

/ Rev. 0

LG Electronics

Use defined Refrigerant

and oil

Any process in where the HCFC’s refrigerant or the

different kind of oil against the defined. Compressor oil

are mixed should be avoided.

Avoid Damage running

The running operation that inspection and the protector

inspection that affect a damage to the function and

durability of the compressor should be avoided

Running dummy indoor

When the outdoor unit is operated with the indoor

dummy unit, the discharged oil should be recovered

enough

Prevent oxidation in pipe

Always purge the system and the compressor with the

dry nitrogen in order to prevent oxidation of the piping

Charging Refrigerant

When charging refrigerant into the cycle, make sure that

refrigerant always be filled from the higher pressure side

(condenser exit) of the cycle.

If liquid refrigerant is sucked in to the compressor liquid

compression occurs, The discharge valve is damaged,

lubrication effectiveness degenerates and reliability drops

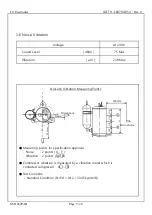

3.3 Process Limit

Page 11 / 24

GVH282PAB

lubrication effectiveness degenerates and reliability drops

noticeably

Avoid Vacuum running

Do not operate the compressor in a vacuum state.

Furthermore do not apply high voltage to a vacuum state

compressor. There is a danger that insulation could

degenerate, causing electric shock

Avoid Air compression

Do not compress the air including the case of leakage in

the refrigeration cycle. If compressors run with air mixed,

inside the compressor is heated and pressurized , which

may cause an explosion

Promptly Assemble

compressor in line

After removing rubber plugs from compressor tubes,

Promptly use the compressor. And do not leave in the

atmosphere for 10 minutes over. If Air gets into the

compressor , accelerating degeneration of the inside of

the cycle or compressor

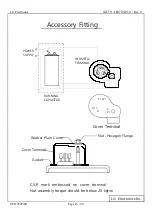

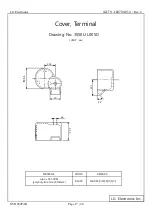

Wiring

Wires connected to the compressor, follow the

compressor specification manual and instructions

Storage temperature

-10℃ ~ 65℃

Earth connection

Use compressor with grounded system only.