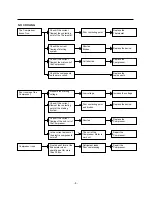

5. TROUBLESHOOTING

- 7 -

DEFECT

EFFECT

CAUSE

REMEDY

GROUP PARTIALLY

OR COMPLETELY

OUT OF

REFRIGERANT

CHARGE

EXCESSIVELY

FULL

HUMIDITY IN THE

SYSTEM

PRESENCE OF AIR

IN THE SYSTEM

BLOCKED

CAPILLARY

MOTOR-

COMPRESSOR

SHORT-CIRCUITED

OR BLOCKED

MOTOR-

COMPRESSOR

DOSE NOT

COMPRESS

NOISY MOTOR-

COMPRESSOR

Evaporator dose not frost even

though motor-compressor runs

continually.

This defect is indicated by the

presence of water outside

refrigerator near the motor caused

by formations of ice on the return

tube.

This defect is indicated by the partial

frosting of the evaporator and by

continual defrosting cycles

determined by the interruption of the

flow of gas on the evaporator. The

motor compressor keeps running.

Poor performance of the refrigerant

system which is indicated: on the

evaporator with a slight frost which

dose not freeze and an excessive

overheating of the condenser and

motor-compressor.

Because of the lack of circulation

Freon in the system, there is no

frosting of the evaporator, while a

slight overheating of the first spiral

of the condenser is noted.

The system dose not work and the

"clixson" intervenes interrupting

delivery to the motor-compressor.

No frost forms on the evaporator

even if the motor-compressor is

apparently running regulary.

In case of mechanical failure in the

motor-compressor there in an

excessive noise when the system is

functioning: in case a suspension

spring is unhooked, banging will be

heard and there will be especially

strong vibrations when the system

starts up and stops.

An empty refrigerant system

indicates a leakage of R

12

. This loss

is generally to be looked for at the

soldering points connecting the

various components or in an

eventual hole in the evaporator

made by the user.

If in the refrigerant system a quantity

of R

12

is introduced which is greater

than that indicated, the excess gas

dose not terminate its expansion in

the evaporator but proceeds into the

return tube.

The refrigerant system is humid

when there is a small percentage of

water present which, not completely

retained by the dehydrator filter,

enters into circulation with the Freon

and freezes at the capillary exit in

the evaporator.

There is air in a refrigerating system

when during the filling phase

vacuum is not effected or it is not

adequately done.

Eventual impurities contained in the

Freon or in the components of the

refrigeration system before

assembly and not retained by the

filter can obstruct the capillary.

In case of short circuit, the

breakdown is due to the electric

winding: if blocked, there is a

mechanical failure in the motor-

compressor.

In this case there is a mechanical

failure in the diaphram valves which:

remaining continually open, do not

permit the piston to suck and

compressor the which

consequentely dose not circulate in

the system.

The cause of the excessive noise is

normally to be sought for in a

mechanical break down, and only

rarely in the unhooking of one of the

suspension springs.

Leakage must be eliminated by

resoldering the defective point or

substituting the damaged

evaporator.

The system must be emptied and

subsequently refilled introducing the

correct quantity of R-134a.

The system must be emptied and

then refilled after eliminating the

humidity.

Group must be drained and

subsequently refilled after carefully

creating vacuum.

To restore the system it must be

emptied, substitute the capillary or

the evaporator entirely in case the

capillary is coaxial with respect to

the return tube, then refill it.

The motor-compressor must be

replaced and then proceed with

refilling.

The motor-comprossor must be

replaced and then proceed with

refilling.

The motor-comprossor must be

substituted and then proceed with

the refilling.