10

LG

Air-Cooled Cooling Only Inverter Scroll Chiller Installation and Owners Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

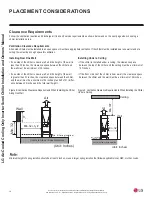

Partial Load Operation

Each cooling cycle operates independently; one (1) cooling cycle

includes two (2) inverter compressors as shown in the diagram.

Two (2) inverter compressors increase the rpm after initial start to

gradually increase the cooling capacity. The user can operate the

chiller smoothly, at optimal conditions, by setting the cooling capac-

ity based on the linear control of LG chiller controller. LG chillers

have efficient partial load performance at any load.

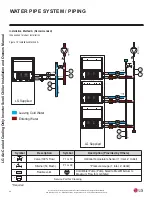

Cooling Cycle Description

The cooling cycle of ACAH series can be described using

the following pressure–enthalpy chart.

༃

,

༄

,

༅

,

༆

,

and

༇

in the following chart shows the conditions of the

refrigerant. The refrigerant comes into the compressor

motor and cools the motor, and becomes overheated and

moves to the suction inlet of the compressor. The oil inside

the compressor seals the gap between the compressor

scrolls and provides lubrication for the bearing to help the

compression of the refrigerant. During this time, the refrig-

erant is compressed and is discharged to the air cooled

condenser. (

༄Ϳ

The compressed refrigerant passes

through the air cooled condenser and exchanges the heat

with the outdoor air. The condensed refrigerant then passes

the condenser to be overcooled. (

༄

ĺ

༅

ĺ

༆

). The refrigerant that passed through the condenser expands in the electronic expansion valve

to flow to the evaporator. (

༆

ĺ

༇

). The refrigerant is evaporated in the shell and tube type heat exchanger, the evaporator. (

༇

ĺ

༃

). Liquid

refrigerant of low temperature pressure passes through the evaporator to cool the water flowing into the evaporator and the refrigerant itself receives

the heat to evaporate to gas condition. (

༃

) The refrigerant continues to change the phase and continuously repeats the cooling cycle.

1

r

o

s

s

e

r

p

m

o

c

d

e

e

p

s

c

it

a

t

Sy

ti

c

a

p

a

c

g

n

il

o

o

C

Load (%)

25%

50%

75%

100%

50%

25%

75%

100%

0%

Inverter

Compressor 1

Inverter

Compressor 2

Cooling Capacity

Capacity (%)

Lubrication System

Oil is efficiently separated inside the scroll compressor, and even when the cycle operates, most of the oil remains inside. Only a part of the

oil will mix with the refrigerant to be circulated within the cycle.

Figure 3: Partial Load Operation Diagram.

Pressure

Enthalpy

Hot-Gas

Suction

-

Compressor

Figure 2: LG Chiller Pressure-Enthalpy Diagram.

INTRODUCTION