4. PCB Assembly Adjustment Method

4-1. Option Adjustment Following BOM

Tool Option

Area Option

Option 1

Option 2

Option 3(Available for EU & Non EU model)

* Profile: Must be changed the option value because being

different with some setting value depend on module, inch

and market

* Equipment : Adjustment Remote Controller

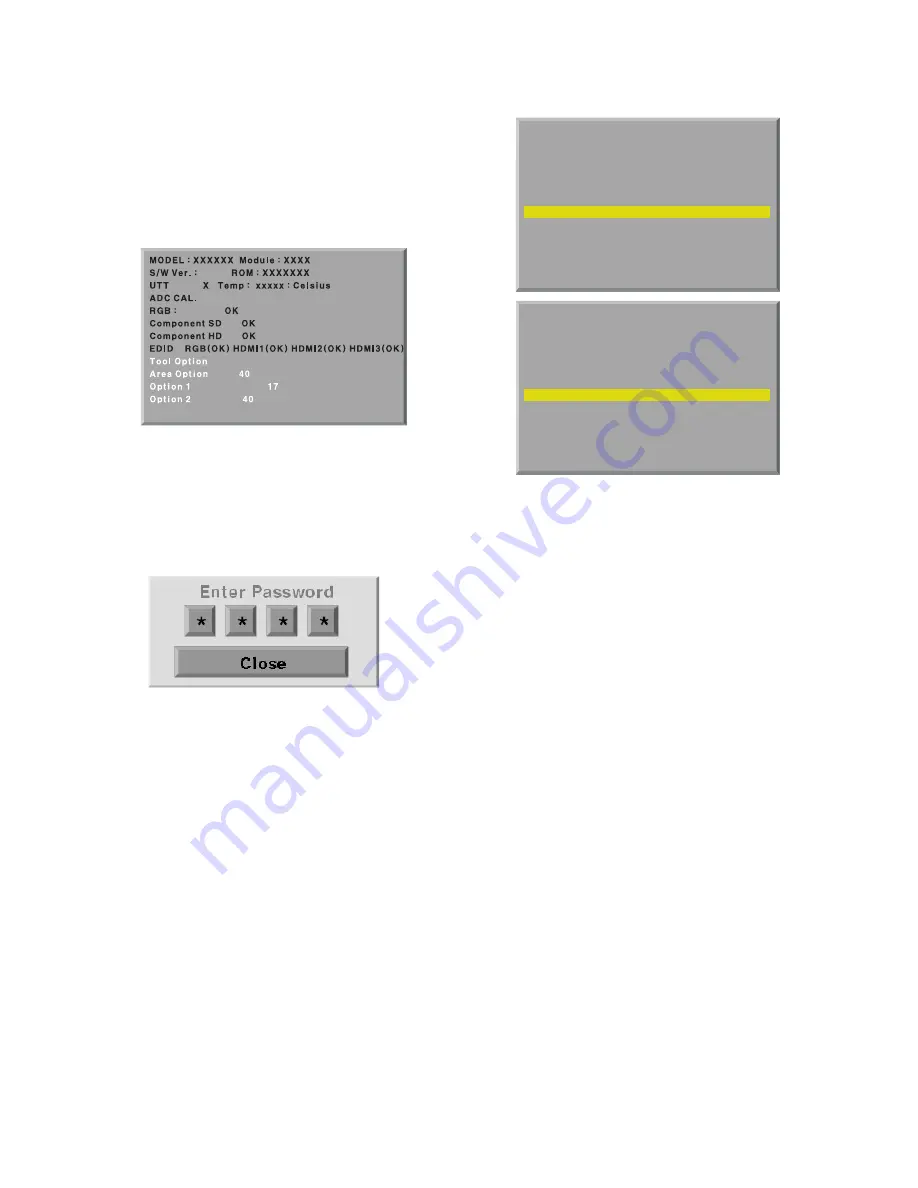

(1) Push the IN-START key in the Adjust R/C.

(2) Enter Password number. The value of Password is “0 0 0

0”.

(3) Input the Option Number that was specified in the BOM,

into the Shipping area.

(4) Select “Tool Option/ Area Option” by using

D

/

E

(CH+/-) key,

and press the number key(0~9) consecutively

ex) If the value of Tool Option1 is 4, input the data using

number key “4” (Fig. 3)

Caution: Don’t Push “IN-STOP” key after PCB assembly

adjustment.

(5) EDID D/L Method

After software D/L or PCBA manufacturing, you can

download EDID Data.

When you adjust Tool Option, H6 Model EDID download

process is executed automatically

* If the model don’t have HDMI 3, HDMI 3 will be disappeared

at OSD Window.

Caution: When you adjust tool option, don’t connect HDMI or D-

sub cable.

If you connect some cable, EDID D/L process will be

failed.

(6) Adjustment method

Before PCBA check, have to change the Tool option and Area

option

* About PDP

After done all adjustments, Press IN-START button and

compare Tool option and Area option value with its BOM, if it

is correctly same then Change “RF mode” and then unplug

the AC cable.

If it is not same, then correct it same with BOM and unplug AC

cable.

For correct it to the model’s module from factory JIG model.

* Don’t push The IN-STOP KEY after completing the function

inspection.

- 9 -

LGE Internal Use Only

Copyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

..

3.09

5

..

MODEL : XXXXXX Module : XXXX

S/W Ver. : X.XX ROM : XXXXXXX

UTT X Temp : xxxxx : Celsius

ADC CAL.

RGB :VV

OK

Component SDV

OK

Component HDV

OK

EDID RGB(OK) HDMI1(NG) HDMI2(NG) HDMI3(NG)

Tool OptionV V

4

Area OptionV V

40V

Option 1V

17

Option 2V

40

..

MODEL : XXXXXX Module : XXXX

S/W Ver. : X.XX ROM : XXXXXXX

UTT X Temp : xxxxx : Celsius

ADC CAL.

RGB :VV

OK

Component SDV

OK

Component HDV

OK

EDID RGB(OK) HDMI1(OK) HDMI2(OK) HDMI3(OK)

Tool OptionV V

4

Area OptionV V

40V

Option 1V

17

Option 2V

40

( Fig. 3)