- 9 -

LGE Internal Use Only

Copyright ©

LG Electronics. Inc. All rights reserved.

Only for training and service purposes

* Auto-control interface and directions

1) Adjust in the place where the influx of light like floodlight

around is blocked. (Illumination is less than 100Lux).

2) Adhere closely the Color Analyzer ( CA210 ) to the

module less than 10cm distance, keep it with the surface

of the Module and Color Analyzer’s Prove vertically.

(80~100°).

3) Aging time

- After aging start, keep the power on (no suspension of

power supply) and heat-run over 5 minutes.

- Using ‘no signal’ or ‘full white pattern’ or the others,

check the back light on.

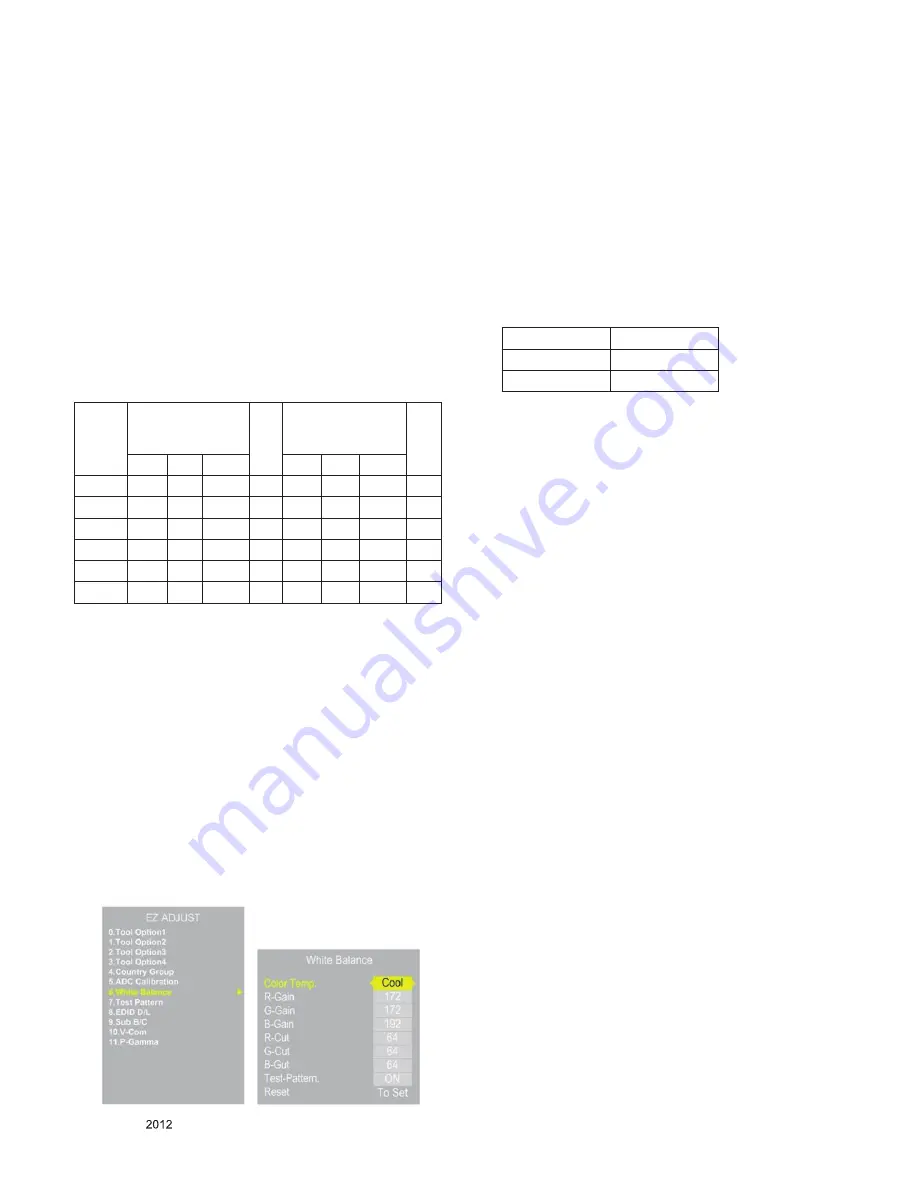

■ Auto adjustment Map(RS-232C)

RS-232C COMMAND

[ CMD ID DATA ]

Wb 00 00 White Balance Start

Wb 00 ff White Balance End

* Caution

- Color Temperature : COOL, Medium, Warm.

- One of R Gain/G Gain/ B Gain should be kept on 0xC0,

and adjust other two lower than C0. (when R/G/B Gain

are all C0, it is the FULL Dynamic Range of Module)

* Manual W/B process using adjusts Remote control.

■ After enter Service Mode by pushing “ADJ” key,

■ Enter White Balance by pushing “►” key at “6. White

Balance”.

■ Stick the sensor to the center of the screen and select

each items(Red/Green/Blue Gain) using ▲/▼(CH +/-)

key on R/C.

■ Adjust R/G/B Gain using◄/►(VOL +/-) key on R/C.

■ Adjust three modes all(Cool/Medium/Warm) : Fix the one

of R/G/B Gain and Change the others.

■ When the adjustment is completed, Enter “COPY ALL”.

■ Exit adjustment mode using EXIT key on R/C.

* After You finish all adjustments, Press “In-start” button and

compare Tool option and Area option value with its BOM, if it

is correctly same then unplug the AC cable.

If it is not same, then correct it same with BOM and unplug

AC cable.

For correct it to the model’s module from factory JIG model.

* Push The “IN STOP KEY” after completing the function

inspection. And Mechanical Power Switch must be set “ON”

* To check the coordinates of White Balance, you have to

measure at the below conditions.

- Picture mode : Vivid, Energy Saving : Off, Below the Ad-

vanced control, Dynamic Contrast : Off, Dynamic Colour : Off

Colour Temp.

-> Picture Mode change : Vivid -> Vivid(User)

4.3. DDC EDID Write (HDMI 256Byte)

-> Not used any more, Use Auto D/L

■ Connect HDMI Signal Cable to HDMI Jack.

■ Write EDID DATA to EEPROM(24C02) by using DDC2B

protocol.

■ Check whether written EDID data is correct or not.

* For SVC main Ass’y, EDID have to be downloaded to Insert

Process in advance.

4.4. EDID DATA

(1) All Data : HEXA Value

(2) Changeable Data :

* : Serial No : Controlled / Data:01

** : Month : Controlled / Data:00

*** : Year : Controlled

**** : Check sum

4.5. EDID DATA Auto Download

(1) Press Adj. key on the Adj. R/C,

(2) Select EDID D/L menu.

(3) By pressing Enter key, EDID download will begin

(4) If Download is successful, OK is display, but If Download is

failure, NG is displayed.

(5) If Download is failure, Re-try downloads.

RS-232C

COMMAND

[CMD ID DATA]

M

I

N

CENTER

(DEFAULT)

M

A

X

Cool Mid Warm

Cool Mid Warm

R Gain

jg

Ja

jd

00

172 192

192

192

G Gain

jh

Jb

je

00

172 192

192

192

B Gain

ji

Jc

jf

00

192 192

172

192

R Cut

64

64

64

128

G Cut

64

64

64

128

B Cut

64

64

64

128

Cool

30

Medium

0

Warm

30

Summary of Contents for 42PN450D

Page 23: ......