5

GENERAL INSTALLATION INSTRUCTIONS

Foundations

Fan foundation must be flat, level and rigid. Where foundation is not completely flat, shims must be

placed under fan support at each anchor bolt as required. Bolting fan to an uneven foundation distorts

alignment and causes vibration.

Structural steel foundations should be heavily cross-braced for load support.

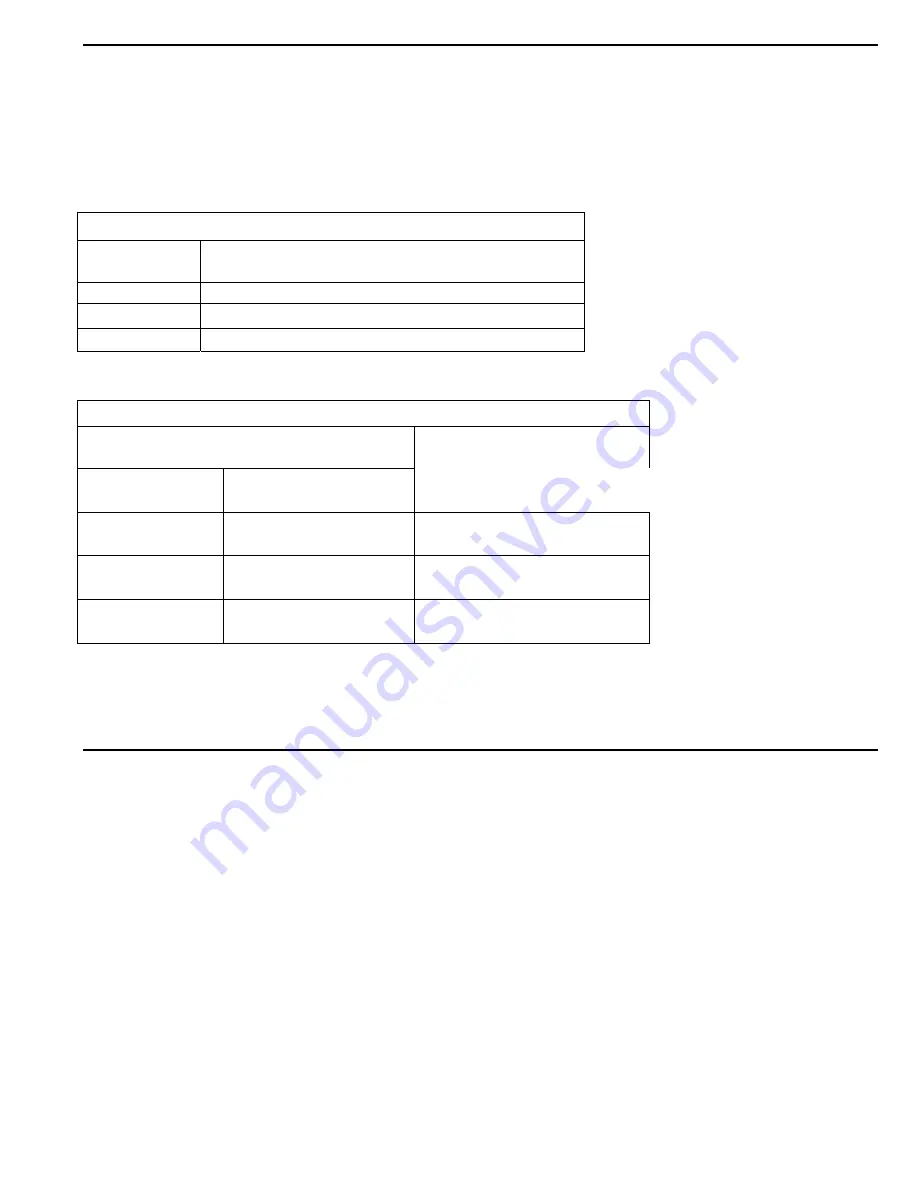

Table #1

TORQUE VALUES FOR SPLIT TAPER BUSHINGS

Bushing Size

MINIMUM RECOMMENDED TORQUE

(INCH-LBS)

H 95

B & P

192

Q & R

350

Table #2

SET SCREW TORQUE VALUES

SET SCREW SIZE

MINIMUM REQUIRED

TORQUE (INCH-LBS)

Diameter & No.

of Threads/Inch

Hex Size Across Flats

(Allen Wrench)

1/4-20

5/16-18

1/8"

5/32"

65

165

3/8-16

7/16-14

3/16"

7/32"

228

348

1/2-13

5/8-11

1/4"

5/16"

504

1104

NOTE:

If wheel set screws are loosened and/or wheel is removed from shaft, set screws

must

be replaced.

Set screws cannot be used more than once. Use knurled, cup point set screws with a locking patch.

OPERATION

Before Connecting Power

1.

Inspect all fasteners and retighten if necessary:

a.

Foundation bolts.

b.

Set screws in fan and wheel and V-belt drive (See Table #1 on preceding page).

c.

Housing, bearing and motor mounting.

2.

Inspection doors should be tight and sealed.

3.

Bearings should be checked for alignment and lubrication (See Bearing Maintenance, pages 4 and 5).

4.

Turn rotating assembly by hand to insure that it does not strike housing. If the wheel strikes the housing,

the wheel may have moved on the shaft or the bearings may have shifted in transit. Correction

must

be

made prior to start up.

5.

Check motor to insure proper speed and electrical characteristics.

6.

Check V-belt drive for alignment and correct belt tension.

7.

After wiring, energize motor for one second to check for proper rotation.