Electrical connection

Leuze electronic

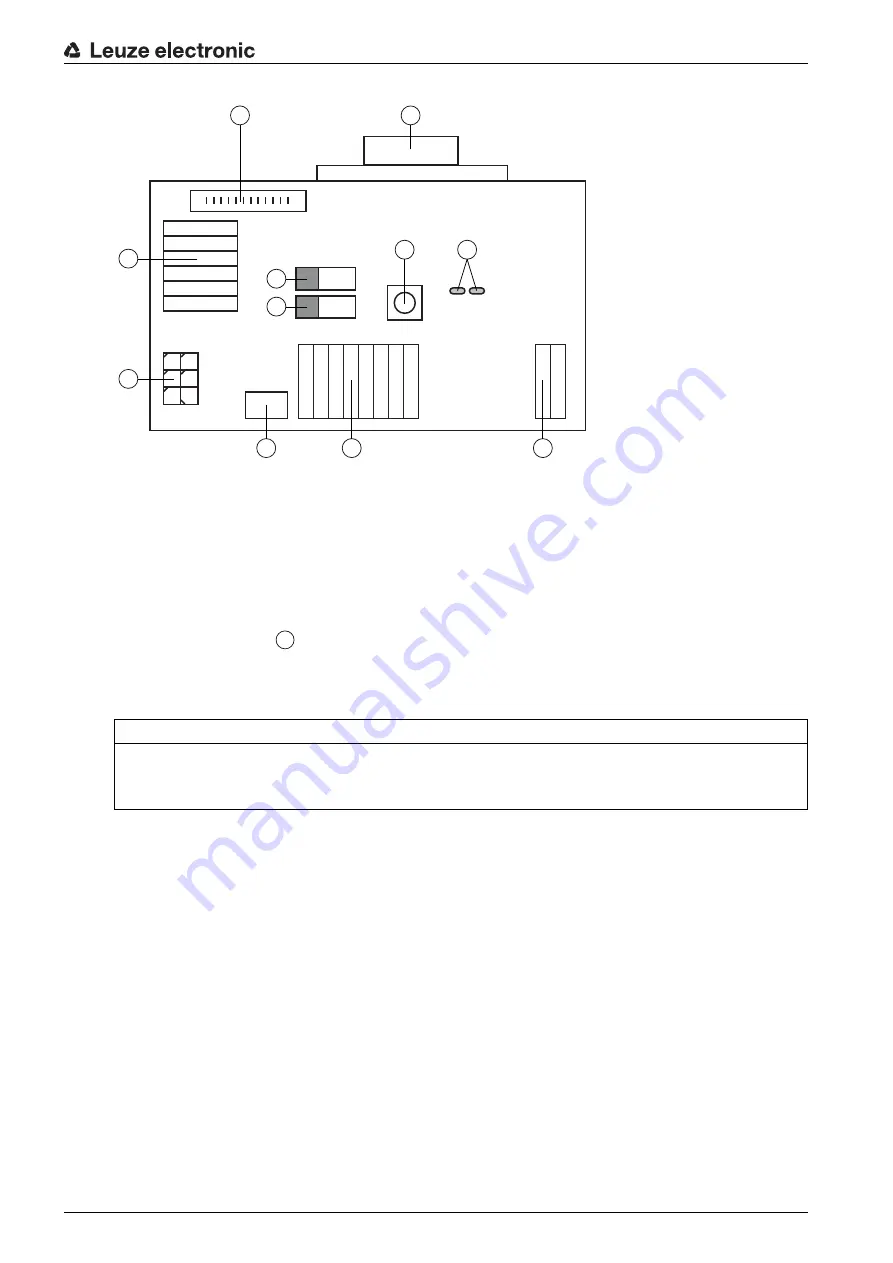

CR 55

13

1

RS 232 connection

2

CR 50 connection

3

CR 100 or CR 55 connection

4

Molex Micro-Fit, 6-pin

5

USB connection

6

Connection to machine control, PLC, external voltage supply 5 VDC

7

External voltage supply 10 … 30 VDC

8

SWIN DIP switch (level for trigger button; 5 V if the scanner high switching input is active, GND if the

low input is active)

9

USB/PWR DIP switch (USB position if voltage is supplied via USB; PWR position if voltage is sup

-

plied via

)

10

Trigger button

11

Status LEDs

Figure 5.3: Connection options for MA-CR adapter circuit board

5.5

Cable lengths and shielding

The maximum cable length is 3 m.

Should a cable extension be necessary, make certain that the cables of the RS 232 interface are shielded.

NOTICE

Using the adapter circuit board

The MA-CR adapter circuit board is intended only for laboratory and test purposes and is not to be

used for industrial applications!

1

2

10

11

3

4

8

9

5

6

7

7