Mounting

Transmission elements

•

Fit or remove transmission elements only using suitable equipment.

•

For fitting the transmission elements use the center hole in the shaft.

•

Avoid impacts and shocks.

•

In case of a belt drive, tension the belt in a controlled manner according to manufacturer information.

•

Be sure to carry out mounting in a manner free from distortion.

•

Compensate minor inaccuracies by suitable flexible couplings.

Fastening

•

Use screws with a minimum property class of 8.8.

•

Observe prescribed starting torques.

•

Secure against unintended loosening.

•

In case of an alternating load, we recommend that you apply an anaerobic curing adhesive between

flange and mounting area.

Gearbox with hollow shaft

•

Use fitting grease in the area of the contact surfaces of machine shaft and hollow shaft bore.

•

Be sure to carry out mounting in a manner free from distortion.

•

Lead forces only across the hollow shaft and not across the housing.

•

For axial fastening, use the snap ring grooves in the hollow shaft.

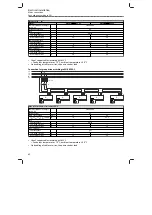

Fig. 2: Proposed solution for axial fastening

Mechanical installation

Mounting

56