Functional test

After commissioning, check all individual functions of the drive:

•

Rotating direction in decoupled state

•

Torque behavior and current consumption

•

Function of the feedback system

•

Brake function

During operation, carry out inspections on a regular basis. Pay special attention to:

•

Unusual noises

•

Irregular running

•

Increased vibration

•

Loose fixing elements

•

Condition of electrical cables

•

Speed variations

•

Deposits on the drive and in the cooling channels

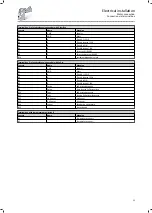

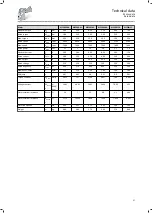

Direction of rotation of the output shaft

L

R

L

R

Motor rotating direction

L

R

Direction of gearbox rotation

2-stage

L

R

3-stage

R

L

4-stage

L

R

Commissioning

Functional test

42