Page 12

New or Replacement Line Set

This section provides information on new installation or

replacement of existing line set. If a new or replacement

line set is not required, then proceed to

Brazing

Connections

If refrigerant lines are routed through a wall, seal and

isolate the opening so vibration is not transmitted to the

building. Pay close attention to line set isolation during

installation of any HVAC system. When properly isolated

from building structures (walls, ceilings. floors), the

refrigerant lines will not create unnecessary vibration and

subsequent sounds.

Also, consider the following when placing and installing a

high−efficiency air conditioner:

REFRIGERANT LINE SET

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (braze connections) to the indoor unit

coil (flare or braze connections). Use Lennox L15 (braze,

non−flare) series line set, or use field−fabricated refrigerant

lines as listed in Table 2.

Table 2. XP Refrigerant Connections and Line Set

Requirements

Model

Valve Field Connections and Recommended

Line Set

Liquid

Line

Suction

Line

L15 Line Set

−024

−030

3/8 in.

(10 mm)

3/4 in.

(19 mm)

L15 line set sizes are dependent

on unit matchup. See Engineering

Handbook to determine correct line

set sizes.

−036

−048

3/8 in.

(10 mm)

7/8 in.

(22 mm)

−060

3/8 in.

(10 mm)

1−1/8 in.

(29 mm)

Field Fabricated

NOTE Some applications may required a field provided 7/8" to

1−1/8" adapter

NOTE − When installing refrigerant lines longer than 50

feet, contact Lennox Technical Support Product

Applications for assistance or Lennox piping manual. To

obtain the correct information from Lennox, be sure to

communicate the following points:

Model (XP) and size of unit (e.g. −060).

Line set diameters for the unit being installed as listed

in Table 2 and total length of installation.

Number of elbows and if there is a rise or drop of the

piping.

MATCHING WITH NEW OR EXISTING INDOOR COIL

AND LINE SET

The RFC1−metering line consisted of a small bore copper

line that ran from condenser to evaporator coil. Refrigerant

was metered into the evaporator by utilizing

temperature/pressure evaporation effects on refrigerant in

the small RFC line. The length and bore of the RFC line

corresponded to the size of cooling unit.

If the XP is being used with either a new or existing indoor

coil which is equipped with a liquid line which served as a

metering device (RFCI), the liquid line must be replaced

prior to the installation of the XP unit. Typically a liquid line

used to meter flow is 1/4" in diameter and copper.

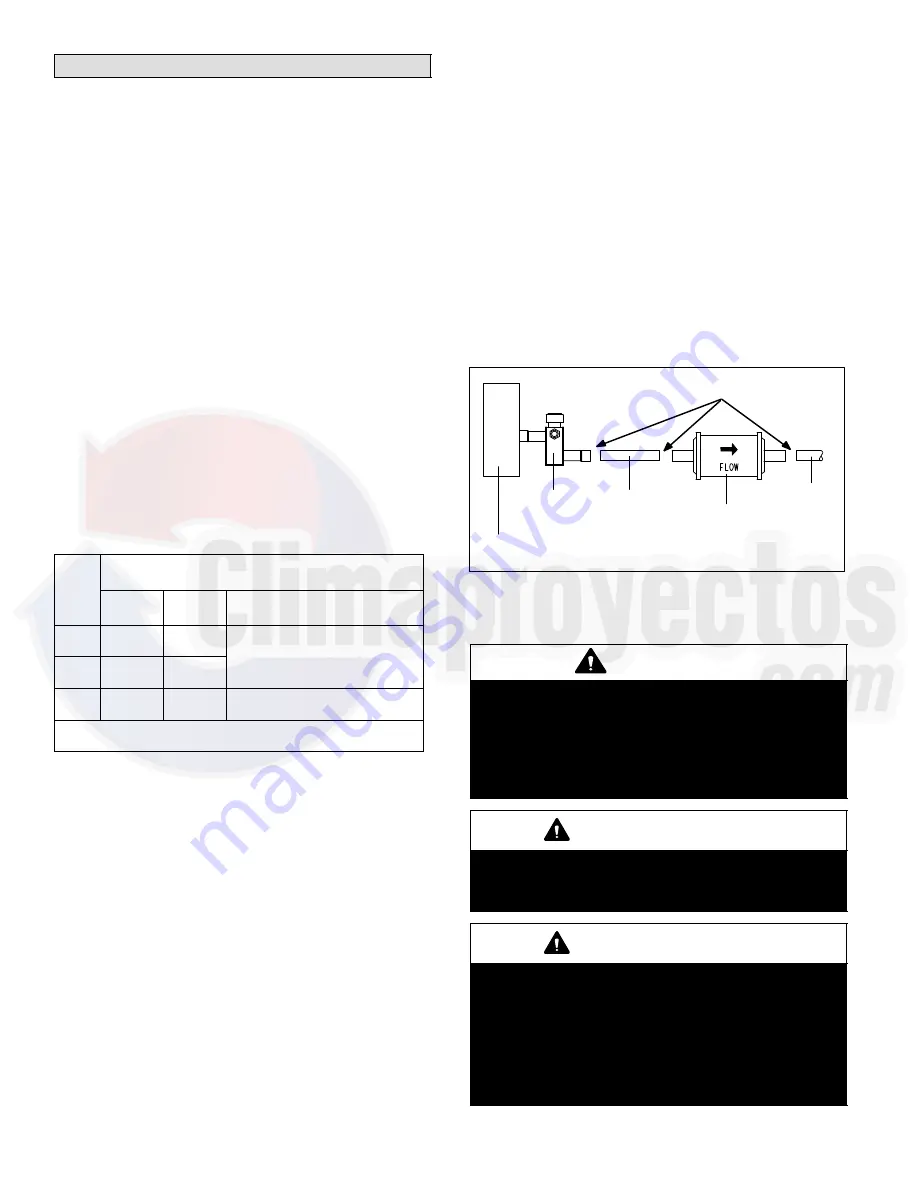

LIQUID LINE FILTER DRIER INSTALLATION OR

REPLACEMENT

The filter drier (one is shipped with each XP unit) must be

field installed in the liquid line between the outdoor unit’s

liquid line service valve and the indoor coil’s metering

device (fixed orifice or TXV) as illustrated in Figure 12. This

filter drier must be installed to ensure a clean,

moisture−free system. Failure to install the filter drier will

void the warranty. A replacement filter drier is available

from Lennox. See

Brazing Connections

on Page 14 for

special procedures on brazing filter drier connections to

the liquid line.

OUTDOOR

UNIT

LIQUID LINE

SERVICE VALVE

LIQUID LINE

FILTER DRIER

LINE

LIQUID

LINE

BRAZE CONNECTION POINTS

Figure 12. Typical Liquid Line Filter Drier

Installation

LINE SET ISOLATION

CAUTION

Brazing alloys and flux contain materials which are hazardous to your

health.

Avoid breathing vapors or fumes from brazing operations. Perform

operations only in well ventilated areas.

Wear gloves and protective goggles or face shield to protect against

burns.

Wash hands with soap and water after handling brazing alloys and flux.

IMPORTANT

The Environmental Protection Agency (EPA) prohibits the intentional

venting of HFC refrigerants during maintenance, service, repair and

disposal of appliance. Approved methods of recovery, recycling or

reclaiming must be followed.

IMPORTANT

If this unit is being matched with an approved line set or indoor unit

coil which was previously charged with mineral oil, or if it is being

matched with a coil which was manufactured before January of 1999,

the coil and line set must be flushed prior to installation. Take care to

empty all existing traps. Polyol ester (POE) oils are used in Lennox

units charged with HFC−410A refrigerant. Residual mineral oil can act

as an insulator, preventing proper heat transfer. It can also clog the

expansion device, and reduce the system performance and capacity.

Failure to properly flush the system per the instructions below will

void the warranty.