2F-85 & 2F-140 - Instruction Manual

3.6. Testing the Gripper with the Robotiq User Interface (RUI)

Once installed and properly secured, your Robotiq 2-Finger Adaptive Gripper should be tested with the Robotiq User Interface test

software using the provided USB converter. Follow these instructions:

1

Install the Robotiq User Interface (RUI). For details, see the Robotiq User Interface manual, available at

Info

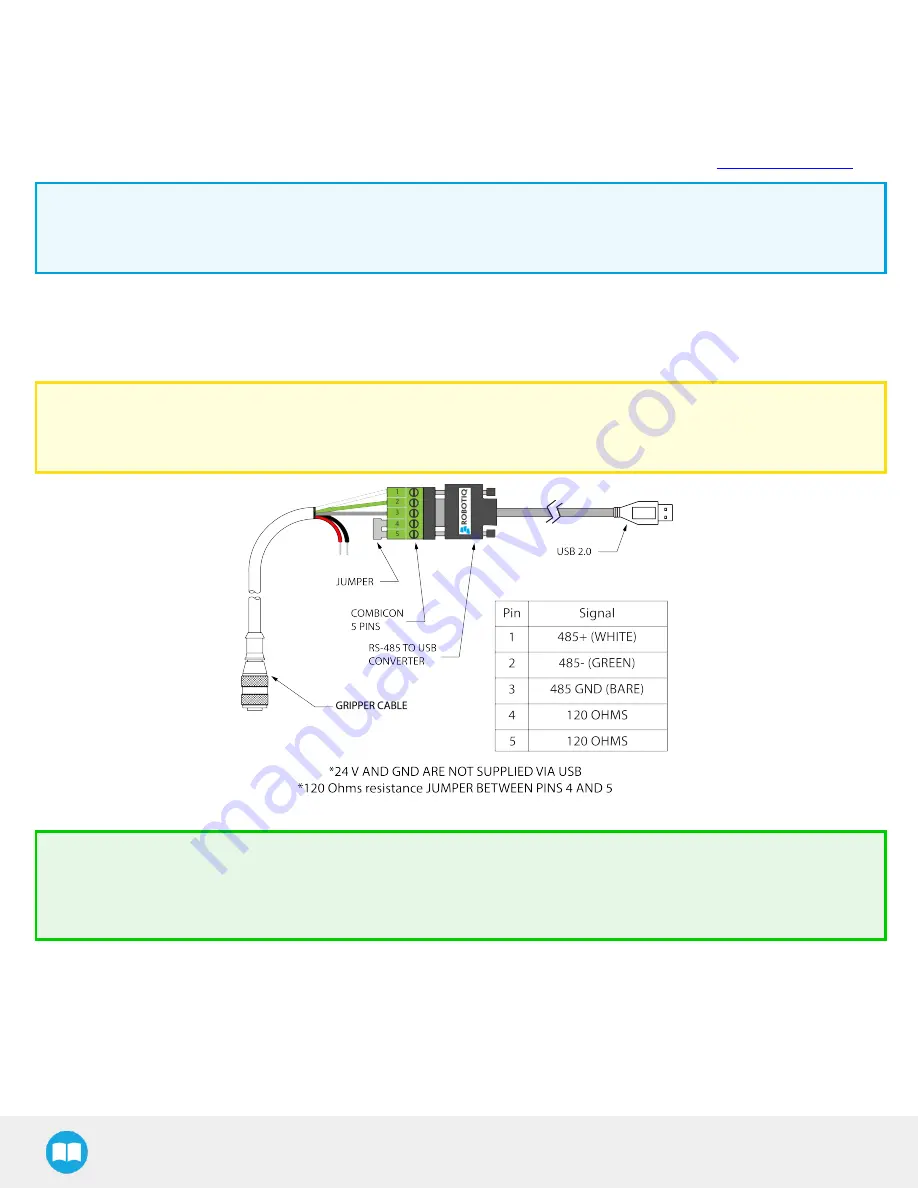

For CB-Series, use the provided RS-485 to USB converter ACC-ADT-USB-RS485 (see RS-485 to USB converter ACC-ADTUSB-

RS485 pinout figure below) to plug into a PC with the Robotiq User Interface installed.

2

Power up your gripper with the previously recommended power supply.

3

Execute the RUI software and select ''auto-connect'' on the connection screen.

4

You are now connected to your gripper, you can click "activate" to begin using the gripper.

Caution

The Activate command will initiate movement of the gripper for auto-calibration procedures. Do not interfere with the

gripper. Be sure you have satisfied robot safety measures.

Fig. 3-18: RS-485 to USB converter ACC-ADT-USB-RS485 pinout.

Tip

With the RUI controlling the gripper, you can go to the view menu to see input and output register values to further your

understanding on how to command the gripper. You can also test grasping objects with various speed and force settings.

See the Control section for details.

36