D

D

C

C

S

S

8

8

1

1

0

0

S

S

D

D

i

i

g

g

i

i

t

t

a

a

l

l

D

D

C

C

S

S

e

e

r

r

v

v

o

o

D

D

r

r

i

i

v

v

e

e

r

r

M

M

a

a

n

n

u

u

a

a

l

l

R

R

e

e

v

v

1

1

.

.

0

0

Tel: (86)755-26434369

5

Website: www.leadshine.com

More about +5V, PUL, DIR, ERR/RES Signals

Pin Function

Details

+5V

+5V Opto-coupler power supply.

PUL

Pulse signal: In single pulse (pulse/direction) mode, this input represents

pulse signal, each rising or falling edge active (software configurable); 4-5V

when PUL-HIGH, 0-0.5V when PUL-LOW. In double pulse mode

(pulse/pulse) , this input represents clockwise (CW) pulse

,

active both at high

level and low level (fixed level software configurable). For reliable response,

pulse width should be longer than 2.5

μ

s. Series connect resistors for

current-limiting when +12V or +24V used. The same as DIR and ENA

signals.

DIR

DIR signal: In single-pulse mode, this signal has low/high voltage levels,

representing two directions of motor rotation; in double-pulse mode

(software configurable), this signal is counter-clock (CCW) pulse

,

active

both at high level and low level (fixed level software configurable). For

reliable motion response, DIR signal should be ahead of PUL signal by 5

μ

s

at least. 4-5V when DIR-HIGH, 0-0.5V when DIR-LOW. Please note that

rotation direction is also related to motor-driver wiring match. Exchanging

the connections of two wires of the motor to the driver and A/B phase signals

of encoder will reverse motion direction.

ERR/RES

ERR/RES Pin: Used to output error and reset the DCS810S to clear errors.

+5 VDC when driver is normal. If protection functions such as over-voltage,

over-current, phase error, encoder error, position following error are

activated, ERR/RES pin will be pulled to LOW level (EGND).

Only

Position

Following Error can be cleared by connecting the E+5V to ERR/RES, and

the users should repower the driver to clear other errors after removing other

related problem(s).

DIP Switch SW1, SW2

There are two DIP switches (SW1 and SW2) can be used to select 4 group servo

parameters stored in EEPROM of the driver. The user can select one group of these

servo parameters to optimize the performance for different applications, in which

using different motors or having different load. For most applications, these two DIP

switches should be both on OFF position (Factory Default Status), saving/selecting

D

D

C

C

S

S

8

8

1

1

0

0

S

S

D

D

i

i

g

g

i

i

t

t

a

a

l

l

D

D

C

C

S

S

e

e

r

r

v

v

o

o

D

D

r

r

i

i

v

v

e

e

r

r

M

M

a

a

n

n

u

u

a

a

l

l

R

R

e

e

v

v

1

1

.

.

0

0

Tel: (86)755-26434369

6

Website: www.leadshine.com

the user

’

s own servo parameters, NOT other 3 group for dedicated applications.

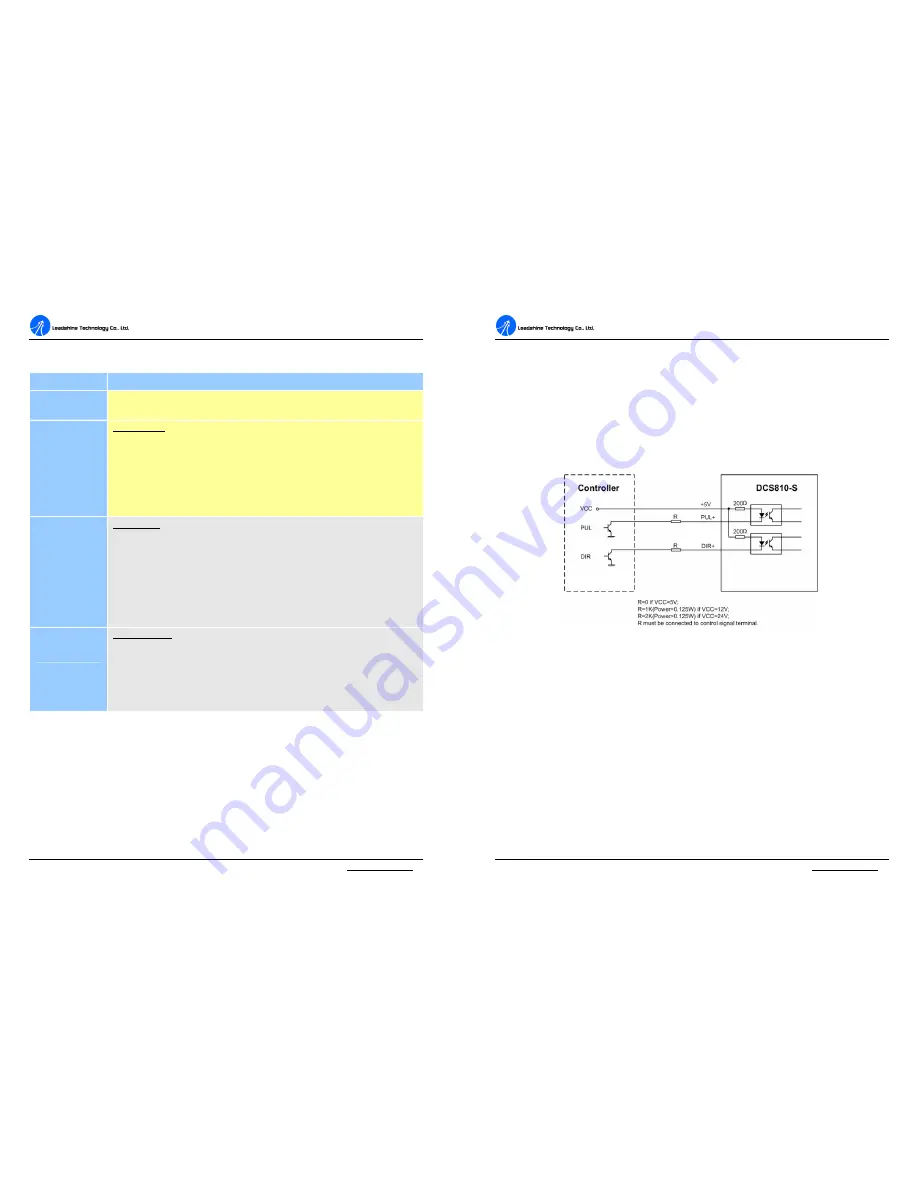

Control Signal Connections

The DCS810S has 2 optically isolated logic inputs to accept PUL/DIR control

signals. These inputs are isolated to minimize or eliminate electrical noises coupled

onto the control signals. In the following figure, connections to open-collector

control signals are illustrated.

Figure 2: Connections to open-collector control signal (common-anode)

Encoder Connections

The DCS810S can accept encoder input from single-ended incremental encoders.

Note that twisted-pair shielded cabling provides the best immunity in electrically

noisy environments.

If the encoder drains less than 50mA, the DCS810S can supply the encoder directly,

and connect it as Figure 3. If the encoder drains more than 50mA, use an external

DC supply and connect it as Figure 4.