5

4.0 OPERATION

4.1 Before Using the Pump:

1. Check all system fittings and connections to be sure

they are tight and leak free.

2. Check oil level in reservoir before operating pump.

Refer to instructions in Section 5.1.

CAUTION

Never add extensions to pump handle.

Extensions cause unstable pump operation.

WARNING

Always keep your body to the side of the

pump, away from the line of force of the handle.

Note:

To reduce handle effort at high pressure, take short

strokes. Maximum leverage is obtained in the last 5° of

stroke.

Note:

When operating a non-vented pump in the vertical

position, the hose end must be pointed down, or the pump

will pick up air and will not build pressure properly.

4.2 Using Two-Speed Pumps

(Models W20307, W20807, W21807, W22607,

X22607, W24507, X24507, W26507 and X26507)

These pumps provide 2-stage flow. Under no-load, the

pump operates in the high flow first stage for rapid advance.

When the load is contacted, the pump automatically

transfers over to the second stage for building pressure.

Note:

Models W22607, X22607, W24507, X24507, W26507

and X26507: when pump pressure reaches approximately

40 bar, you must momentarily stop pumping and raise the

handle to shift to the high pressure stage. After the pump

shifts, pumping will require less effort.

4.3 Single-Acting Applications with Release Valve

(Models W10607, W11407, W20307, W20807,

W21807, W22607 and W24507)

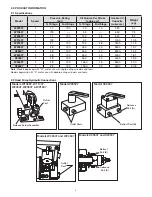

1. Close release valve by turning clockwise, as shown in

Figure 1.

Figure 1

CAUTION

Close release valve -

HAND TIGHT ONLY

.

Using tools on release valve can damage it and cause the

pump to malfunction.

2. Operate pump handle to deliver hydraulic power to

system. Pressure will be maintained until release valve

is opened.

3. Open release valve (turn counter-clockwise) to release

pressure, allowing oil to flow back to the reservoir.

Slowly open release valve to release the pressure and

control the flow of oil back to the reservoir.

Note:

The amount that the release valve is opened controls

the speed of the oil returning to the pump and the retract

speed of the cylinders lowering the load.

4.4 Single-Acting Applications with 3-Way, 2 Position

Manual Valve (Model W26507)

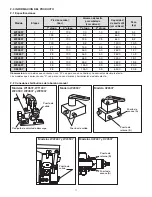

1. Shift the valve lever to the

advance

position. See

Figure 2, position 2.

Figure 2

2

1

2

1

A

A

Retract

Advance

Valve Positions - Model W26507

2. Operate pump handle to deliver hydraulic power to the

system. Pressure will be maintained until the valve is

shifted.

3. Slowly shift the valve lever to the

retract

position to

release pressure and control the flow of oil back to the

reservoir. See Figure 2, position 1.

The amount that the valve is opened controls the

speed of oil returning to the reservoir and the retract

speed of the cylinder(s) lowering the load.

Note:

Model W26507 is equipped with a directional control

valve. Inline system check valves are recommended for

controlling cylinder movement under load with this pump

model.