Lantronix

ION001-A Install Guide

33419 Rev. E

6

Powering the Chassis

To supply power to the single-slot chassis:

1.

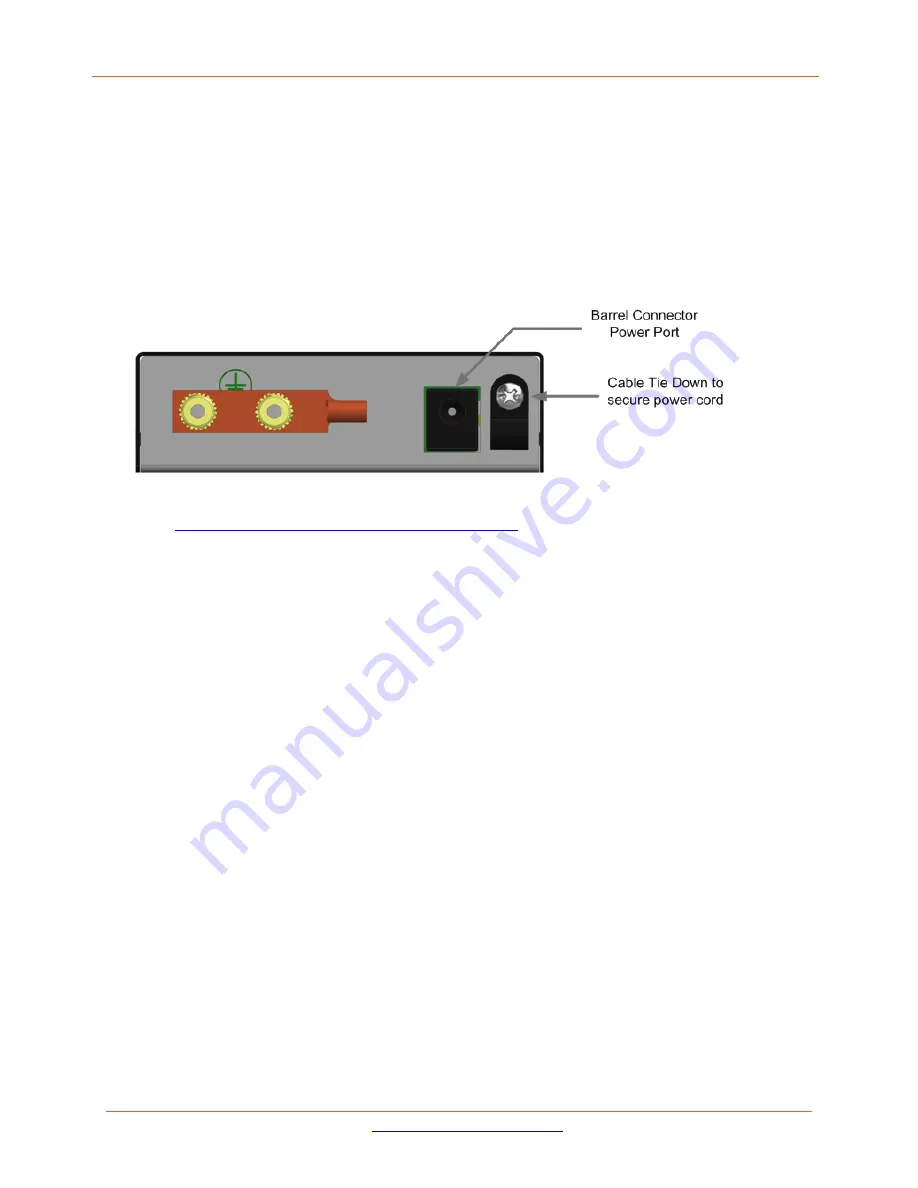

Connect the barrel connector on the power adapter to the ION001-A back panel Power port.

2.

Connect the power adapter plug to AC power.

3.

Use the cable tie down to secure the power supply cord and the barrel connector.

4.

Verify that the single-slot chassis is powered by observing the lit LED(s) on the installed slide-in card.

See the related slide-in card manual for LED and other details.

For an optional DC power source see the SPS-2460-SA

External Power Supply 24-60 VDC and 24-42 VAC

rms

https://www.lantronix.com/products/sps-2460-sa/

Grounding the Chassis

The single-slot chassis comes equipped with grounding lugs located on its back panel. They require a

grounding conductor wire terminated with a two-hole, compression-type, grounding connector

(not

provided)

. The grounding wire

(must be a copper conductor)

is not included with the chassis and must be

provided by the customer/installer. The electrical-conducting path from the single-slot chassis must:

•

Flow via the grounding lugs to the common bonding network (CBN) for telecom installations, or to

an alternative approved grounding system

(if required)

for non-telecom installations.

•

Be of sufficiently low impedance to conduct fault currents likely to be imposed on the converter.

•

Enable proper operation of any over-current protection devices.

Ground Wire Size

The wire size of the Protective Earth

(ground)

conductor should be greater than or equal to the wire size

of the power source conductors. The power-source conductor wire size is installation dependent and

sized to accommodate acceptable IR losses between the power source and the device power terminal.

The device terminal block accommodates #6 wire lugs. A #6 wire lug typically terminates #16 - #20 wire;

with #18 most common.

Connecting the Ground Wire

The conductor must be fastened to the grounding lugs with the enclosed antirotation star-washers and

lug-nut fasteners. The torque requirement for the connector lug-nut fastener is specified by the

connector’s manufacturer.