ELECTRICAL SYSTEM

4-7

Replacing the Seat Switch

1.

Set the key switch to OFF, remove the key from the

key switch and place in a secure area.

2.

Apply the parking brake, perform a Lock Out/Tag Out

procedure, disconnect battery and block all wheels.

3.

Remove the hardware securing the front portion of

the seat slide rails to the cover. Then loosen the back

two sets of hardware.

4.

Raise the front of the seat up to expose the switch

and cable mounting.

5.

Have a helper disconnect the switch cable from the

main harness, then unscrew the switch assembly.

6.

Install the new switch and cable by performing the

preceding steps in reverse order.

7.

Before placing the truck back into operation, test it to

be sure the switch functions properly. See “Check

Driver’s Seat Switch” on page 4-6.

Truck Lighting

Trucks equipped with optional lighting, flashing or spot

lights may contain replaceable bulbs, or the housing may

be replaced as a whole. Lighting replacement varies

according to the manufacturer.

Headlights

These lights have non-replaceable LED elements and

are replaced as an entire unit.

Brake and Tail Lights

1.

Set the key switch to OFF and remove the key.

2.

Apply the parking brake and disconnect the battery.

3. The complete LED light assembly must be replaced

to repair a faulty light assembly.

4.

Pull off the complete LED light assembly. Exercise

care to avoid breaking the LED assembly.

5.

Disconnect the wire connector and remove the

bracket that is attached to the overhead guard.

6.

If shielding or guard covers are involved, make

certain that the guard is replaced after the repair.

7.

Reassemble in reverse order.

Back Up Alarms

1.

Set the key switch to OFF and remove the key.

2.

Disconnect the battery.

3. To replace the alarm assembly, disconnect the wire

connector and remove the mounting hardware

holding the alarm to the overhead guard.

4.

Reassemble in reverse order.

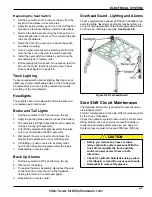

Overhead Guard, Lighting and Alarms

Trucks equipped with optional LED flood / headlights, tail

and stop lights, flashing or spot lights (strobe lights), etc.

do not contain replaceable bulbs. Bulb replacement must

be done as a complete assembly. See Figure 4-8.

Figure 4-8 Overhead Guard

Side Shift Circuit Maintenance

The following information is provided for authorized ser-

vice facilities ONLY.

Perform maintenance on the side shift circuit as required

by the Hourly Checklists.

Check the hydraulic system pressure at the control valve

fitting. Refer to the truck service manual for details on

measuring hydraulic system pressure, see page 3-3.

System pressure must not exceed 3000 psi (206 bar).

CAUTION

• Before you remove any hoses or tubes,

relieve hydraulic system pressure. With the

truck off, manipulate the truck auxiliary

control valve(s) several times in both

directions.

• Check for hydraulic fluid leaks using a piece

of cardboard or wood. Do not use your hands.

• Remember to wear safety glasses.

https://www.forkliftpdfmanuals.com/