4-8.3

Emergency Relay Valve Maintenance

Every 3600 operating hours, 100,000 miles, or

yearly, the Emergency Relay Valve should be dis-

assembled, cleaned, and lubricated by a trained

technician.

WARNING

REPAIR OR REPLACEMENT OF THE

RELAY/EMERGENCY VALVE IS A COM-

PLEX OPERATION AND SHOULD BE

PERFORMED BY TRAINED SERVICE

PERSONNEL. CONTACT A LANDOLL

AUTHORIZED SERVICE CENTER OR

THE LANDOLL FACTORY FOR SERVIC-

ING.

4-8.4

Brake Assembly Maintenance

The brake assemblies should be inspected and

adjusted every 2,000 miles or monthly. Examine

the brake linings visually to locate the lining show-

ing the greatest amount of wear. The wheel and

drum should be removed and the linings replaced

if the thinnest portion of the lining is 3/8 in. (9.5

mm) or less. Do not allow the linings to wear thin

enough that the lining rivet contacts the drum.

(See

Figure 4-12)

. Lubricate brake assembly per

Figure

4-1, Lubrication Points

and

Table 4-2, Mainte-

nance Schedule.

WARNING

DO NOT ALLOW GREASE TO CON-

TACT BRAKE LININGS AS THIS

COULD RESULT IN REDUCED BRAK-

ING PERFORMANCE.

a. Brake Adjustment

This semitrailer is equipped with automatic

slack adjusters which compensate for brake lining

wear and keep brakes adjusted. Brakes should not

be adjusted manually except when relining brakes.

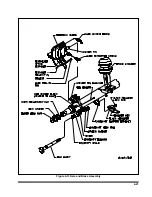

b. Disassembly for 12-1/4" X 7-1/2" Brakes

(See Figure 4-13)

1.

Release brakes and back off slack

adjuster.

2.

Remove slack adjuster lock ring and slack

adjuster.

3.

Remove drum assembly

(See Figure

4.

Remove anchor pin retainers, washers,

and bushings.

5.

Remove anchor pins and brake shoes.

6.

Remove brake return springs.

7.

Remove camshaft lock ring, spacer washer

and camshaft

8.

Remove roller pin retainers.

9.

Remove roller pins and rollers from shoes.

10.

Remove camshaft bushings and seals from

spider.

11.

After removing the shoes, completely

inspect all brake components, servicing

as necessary.

4-20

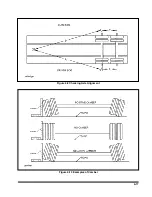

Figure 4-12 Brake Lining Wear

Summary of Contents for 600B Series

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

Page 18: ...3 6 Figure 3 4 Hydraulic Controls...

Page 26: ...3 14 Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 20 Figure 3 10 Dock Leveler Operation...

Page 38: ...3 26 Figure 3 14 Rear Impact Guard and Antilock Brake System...

Page 42: ...4 2 Figure 4 1 Lubrication Points...

Page 48: ...4 8 Figure 4 3 600B Wiring Diagram...

Page 49: ...4 9 Figure 4 4 Remote Wiring Diagram...

Page 52: ...4 12 Figure 4 5 Tandem Axle Air Ride Suspension System Figure 4 6 Air Ride Height Adjustment...

Page 54: ...4 14 Figure 4 7 Triple Axle Air Ride Suspension System...

Page 57: ...4 17 Figure 4 9 Checking Axle Alignment Figure 4 10 Examples of Camber...

Page 61: ...4 21 Figure 4 13 Axle and Brake Assembly...

Page 71: ...4 31 Figure 4 21 Dock Leveler Leg Assembly...

Page 73: ...4 33 Figure 4 22 Crank Landing Gear Assembly...

Page 84: ...NOTES 5 10...