Section 1: Assembly & Set-up

2/10/21

14

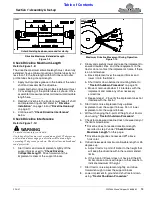

Discharge Chute Assembly

Figure 1-2

Discharge Chute

Refer to Figure 1-2:

1. Loosen the four rear bolts (#9) by two or three turns.

Do not remove bolts or nuts securing bolts.

2. Remove the four front bolts (#8), half-clamp

plate (#7), and half-spacer plate (#5) from discharge

spout (#1). Keep hardware for reuse.

3. Make sure bottom half-clamp plate (#4) is positioned

against underside of notched plate (#2). Being

careful not to damage plastic bearing (#11), slide

front of discharge chute (#1) onto notched plate (#2)

until discharge chute is centered over the notched

plate.

4. Place half-spacer plate (#5) on top of half-clamp

plate (#7) with bolt holes in alignment with each

other.

5. Position bottom half-clamp plate (#9) against

underside of notched plate (#2) as shown.

6. Bolt chute (#1) to half-spacer plate (#5) and half-

clamp plate (#7) with the four removed 1/4”-20 x 3/4"

GR5 cap screws (#8) and hex locknuts (#10).

7.

Draw all eight hex locknuts (#10) up snug and then

back each one off 1/2 turn.

35681

NOTE:

Half-clamp plate (#7) and half-spacer

plate (#5) are shipped bolted to discharge spout (#1).

IMPORTANT:

Be careful not to damage plastic

surface attached to underside of discharge chute

while attaching chute to the chipper’s notched plate.

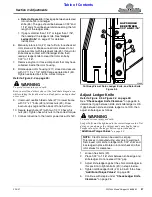

4" Feed Chute Assembly

Figure 1-3

Feed Chute

Refer to Figure 1-3:

WARNING

!

To avoid serious injury or death:

Keep yourself and others clear of the feed chute hinged area

while rotating the feed chute down. Body parts can be pinched

1. Remove nuts (#3) from bottom of feed chute (#1).

2. Hold feed chute (#1) up and pull linchpin (#4).

3. Rotate pivoting latch (#2) 90

o

clockwise and lower

feed chute (#1) down.

Refer to Figure 1-4 on page 15:

4. Insert linchpin (#4) in hole “A” to secure pivoting

latching in its rotated position.

5. Check ledger clearance before continuing. Refer to

“Check Ledger Knife Clearance”

6. Secure feed chute (#1) with two 1/2"-13 hex whiz

nuts (#3). Tighten nuts to the correct torque.

Inspect Twig Breaker Bar

The twig breaker bar (#5) should be inspected to make

certain it is centered in the rotor fin slots. See

on page 30 for detailed adjustment and

maintenance instructions.

35678