22

Section 3: Operating Instructions

RCR1884 Series Rotary Cutter 312-880M

2/03/12

Table of Contents

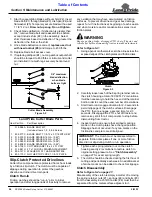

Blade Engagement & Disengagement

Cutter blades can lock-up against each other during

start-up and shut-down especially if the tractor’s PTO

engagement is “INSTANT ON” and “INSTANT OFF”.

Following Blade Engagement and Blade Disengagement

instructions on page 22 will help eliminate blade lock up.

Blade Engagement

1.

Increase throttle to a speed just enough to get the

cutter started without stalling tractor while slowly

engaging PTO drivelines. Use tractor’s PTO soft start

option if available.

2.

Ensure that all power shafts are rotating and that the

cutter is not vibrating excessively after ramping up to

PTO speed for at least 3 seconds. If excessive

vibration continues after 3 seconds at full PTO

speed, disengage PTO immediately, shut down

tractor, and remove switch key.

3.

Check blades for a lock-up situation. Block cutter

deck up before working under the unit. Unlock

blades, remove support blocks, and repeat “Blade

Engagement” instructions.

Blade Disengagement

1.

Slowly decrease throttle speed until engine idle

speed is reached and then disengage PTO.

2.

Engage tractor park brake, shut tractor engine off

and remove switch key. Stay on tractor until blades

have come to a complete stop.

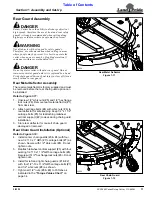

Field Operation

!

WARNING

Clear area to be cut of debris and other unforeseen removable

objects before cutting. Mark any potential hazards that cannot

be removed such as tree stumps, post, rocks, holes, and drop-

offs with a visible flag.

IMPORTANT: Maintain correct PTO speed. Loss of

PTO speed will allow blades to swing back resulting

in a ragged, uneven cutting. Excessive engine speed

will cause damage to the power train components.

IMPORTANT: Your Rotary Cutter is equipped with

free swinging cutting blades to reduce shock loads

when striking obstacles. However, it is best to avoid

striking obstacles to extend cutter and blade life.

1.

Thoroughly inspect area to be cut for debris and

unforeseen objects. Mark any potential hazards.

2.

Follow “Blade Engagement” instructions on this

page to start cutter blades turning.

3.

Optimum ground speed depends on density of

material being cut, horsepower rating of tractor, and

terrain. Always operate tractor at cutter’s full rated

PTO speed in a gear range that allows the cutter to

make a smooth cut without lugging tractor down,

usually between 2 to 5 mph.

4.

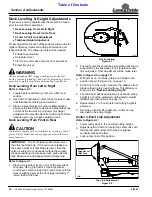

Stop traveling and disengage PTO after the first 50

feet of cutting. Check cutter levelness and cutting

height to make certain it is adjusted properly.

5.

Do not engage PTO with 3-Point cutter fully raised.

6.

Periodically disengage PTO, shut down tractor,

remove key, and check for foreign objects wrapped

around the blade spindle. Block cutter deck up before

removing objects.

7.

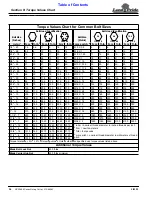

Frequently inspect cutter for loose bolts and nuts.

Tighten all loose bolts and nuts as indicated in the

“Torque Values Chart” on page 34.

8.

For additional information, see “General Operating

Instructions” on page 23.

Un-hooking the Rotary Cutter

Un-hook Rotary Cutter from the tractor as follows:

1.

See “Long Term Storage” on page 27 if cutter is to

be stored for a long time.

2.

Park on a level solid surface and lower deck to

ground level or onto support blocks.

3.

Engage tractor park brake, shut tractor engine off,

and remove switch key. Stay on tractor until blades

have come to a complete stop.

4.

Disconnect driveline and safety chain from tractor.

5.

Unhook 3-Point hitch from tractor and drive tractor

forward several feet.

6.

Reinstall hitch pins, linch pins, and hair pin cotters in

cutter hitch for safe keeping.

7.

Collapse driveline by pushing tractor end of driveline

towards cutter gearbox.

8.

Support collapsed driveline off the ground.

NOTE: Do not cut in wet conditions. Wet material

will build up on the deck underside creating poor

discharge, high wear, and additional horsepower.

Periodically disengage PTO, turn off tractor, remove

key & check for objects wrapped around blade

spindle. Block deck up before removing objects.

Frequently inspect cutter for loose bolts and nuts.

Tighten all loose hardware as indicated in the

“Torque Values Chart” on page 34.