Section 1: Assembly & Set-Up

RCF3096, RCF3010, & RCFM3010 Rotary Cutters 326-566M

11/8/18

27

Check Driveline Clearance

WARNING

!

To avoid serious injury or death:

1.

Lubricate driveline If it has not be lubricated. Refer to

2. Assemble driveline profiles if they are separated.

3. If the driveline is not installed to the implement and

hooked to the tractor, do so now. Refer to:

•

“Driveline Installation (3-Point)”

•

“Driveline Installation (Semi-Mount)”

•

•

“Driveline Hook-up (Semi-Mount)”

4. Start tractor and raise implement slightly off the

support blocks. Drive forward until the implement is

clear of the support blocks.

5. Slowly and carefully lower and raise cutter to ensure

drawbar, tires, and other equipment on the tractor do

not contact the cutter frame. If there is an

interference:

a. Back cutter over the support blocks and lower it

onto the blocks.

b. Shut tractor down before dismounting. Refer to

c. Move or remove drawbar if it interferes with the

cutter and make any other necessary corrections.

d. Repeat steps 1-5 to verify the cutter does not

interfere with the tractor.

6. Start tractor and raise implement fully up. If

implement is not above the support blocks, back

implement over the support blocks. Do not lower

implement onto the support blocks.

7.

Without changing the 3-point lift height, shut tractor

down using

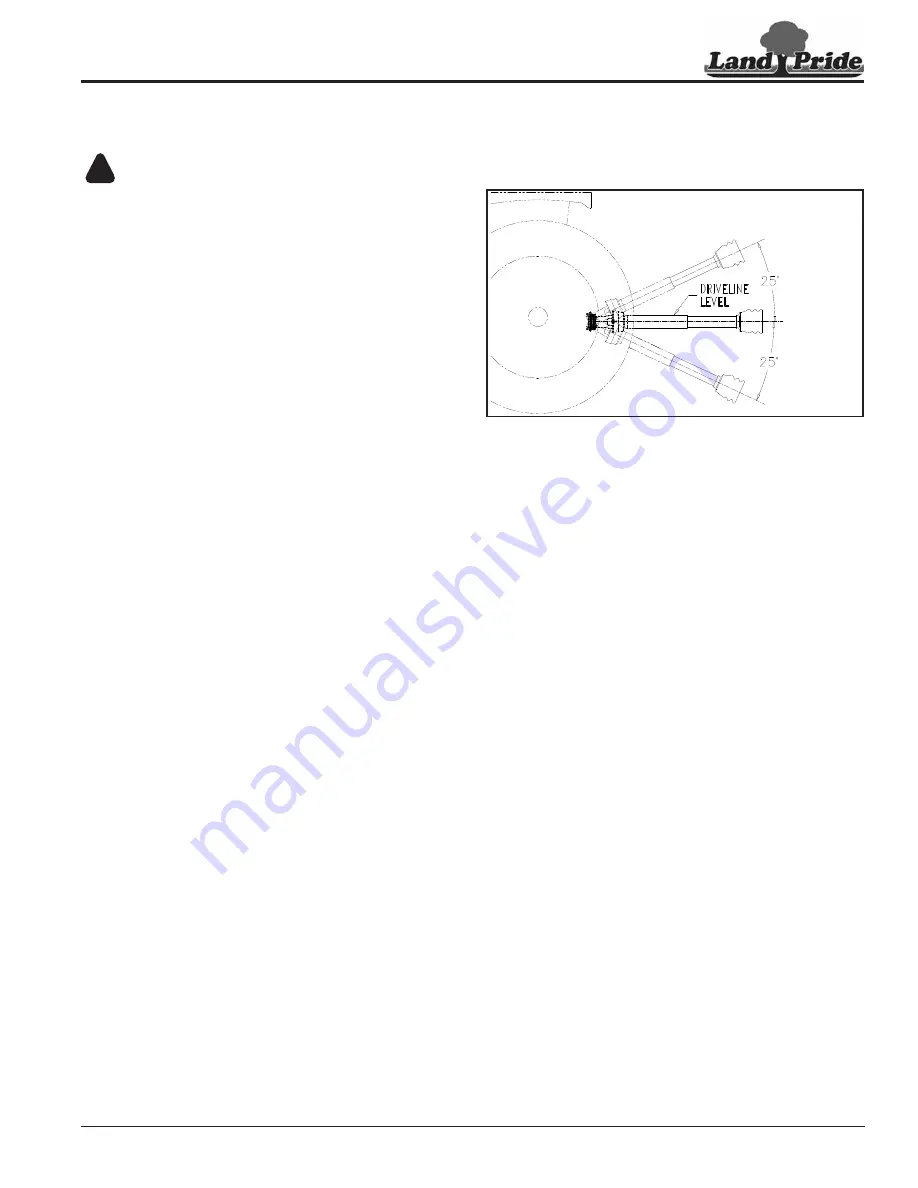

8. Check to make sure the driveline angle does not

exceed 25 degrees above horizontal as shown in

Figure 1-21.

9. If driveline angle exceeds 25 degrees above

horizontal, adjust 3-point lift height as follows:

a. Adjust tractor 3-point lift limiter to the height that

will keep the driveline within the recommended lift

angle.

b. If the 3-point left lever does not have a lift height

limiter, make a mark with tape or other means to

indicate maximum lift height.

10. Start tractor and drive forward enough to clear the

support blocks.

11. Lower implement to ground and shut tractor down

using

Maximum Driveline Movement During Operation

Figure 1-20

24872