Section 5: Maintenance & Lubrication

7/13/20

RCD1884 Rotary Cutters 326-355M

27

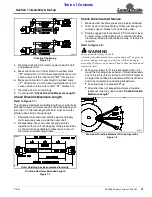

Cutter Blade Assembly

Figure 5-1

33002

Counterclockwise

Blade Rotation

Use 1-11/16"

Socket Wrench

On Blade Nut (#3)

Land Pride Cutter Blade Parts

Item Part No. Part Description

318-586A BLADE BOLT KIT (items 1, 2, & 3 below)

1 802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

2 804-147C WASHER FLAT 1 HARD ASTMF436

3 803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

4 326-234H ROUND DISHPAN WELDMENT

5 840-273C PLUG LP 3" ID RUBBER

6 820-443C CUTTER BLADES 1/2" x 4" x 16" LG. CCW

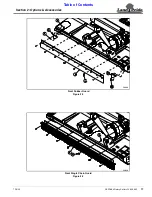

Blade Rotation & Timing

Figure 5-2

Refer to Figure 5-2 on page 27:

9. Make certain when installing cutter blades that the

blades on one spindle is positioned 90 degrees to the

blades on the other spindle as shown in Figure 5-2.

10. Carefully check cutting edges of blades in relation to

blade rotation to ensure correct blade placement.

Blade rotation is counterclockwise with cutting edge

leading. See Figure 5-2 on page 27. Airfoil (lift) must

be oriented towards the top of the deck.

WARNING

!

To avoid serious injury or death:

A locknut that has been removed can lose its thread locking

properties. Reusing a used locknut can result in a thrown

blade. Always use a new locknut when installing blades.

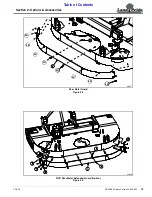

11. Insert blade bolt (#1) through blade (#6), dish

pan (#4), and flat washer (#2). Secure blade with a

new locknut (#3)

and torque to 450 ft-lbs.

12. Repeat step 11 for the other blade.

13. Replace access cover (#5).

14. If replacing dishpan (#4), castle nut (#7) on gearbox

output shaft should be torqued to 450 ft-lbs. minimum

and secured with cotter pin (#8) with both legs bent

opposite directions around the nut.

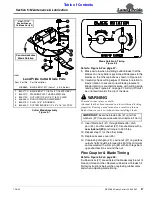

Flex Coupler & Blade Timing

Refer to Figure 5-3 on page 28:

If rubber discs (#7) are wrinkled, the blades may be out of

time and hit each other. Replace rubber disc if blades hit.

Follow instructions below when replacing rubber discs

and when adjusting blade timing.