6

Adjust Water Flow Rate & Syrup/Water Ratio

1.

Remove valve cover from first valve.

2.

Close syrup shut-off at mounting block for first valve.

4. Remove nozzle by twisting counter clockwise and pulling

down, then remove diffuser by pulling down.

Ensure there is ice on the cold plate and the lines are

cold before attempting to set the flow rates on the

valves. The drink temperature should be no higher than

40°F (4.4°C) when flow rates are set.

NOTE

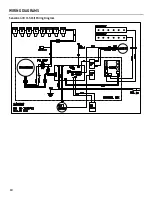

A

B

Increase

Decrease

C

E

A. Flow Control, Water

B. Flow Control, Syrup

C. Nozzle (Diffuser inside)

D. Retainer Clip

E. Soda Lever

D

A

B

A. Syrup Seperator

B. Soda Lever

A

B

A. Water ON

B. Syrup Closed

A

B

A. Nozzle

B. Diffuser

C. Soda Lever

C

A

B

C

A. Syrup Seperator

B. Ratio Cup

C. Verify Soda/

Water Level

6.

Re-open syrup shut-off at mounting block.

7.

Activate valve to purge syrup until steady flow is achieved.

8. Using a Lancer brix cup, activate the valve and capture a

sample. Verify that the syrup level is even with the water

level. Use a screwdriver to adjust if needed.

9. Remove syrup seperator and reinstall nozzle. Replace valve

cover.

10.

Repeat steps 1-8 for each valve.

11.

Re-install merchandiser, splash plate, and top cover.

12. Activate each valve until the carbonator pump comes on.

Release the button, allow carbonator to fill and stop. Repeat

this process until a steady flow of carbonated water is

achieved.

13. Activate each valve to purge air from the syrup lines.

The pump deck has a 3 minute timeout feature. If the

timeout occurs, turn the deck OFF then ON by flipping

the switch on the control box.

NOTE

To check for CO

2

leaks, close the valve on the CO

2

cylinder and observe if the pressure to the system

drops with the cylinder valve closed for five minutes.

Open the cylinder valve after check.

NOTE

3.

Using a Lancer ratio cup verify water flow rate (5 oz. in 4

sec.). Use a screwdriver to adjust if needed.

5. Install Lancer (yellow) syrup seperator

(PN 54-0031)

in place

of nozzle.