3

INSTALLATION

Unpack the Dispenser

1. Cut package banding straps and remove.

2. Open the box and remove the accessory kit and loose parts.

3. Carefully remove the dispenser from the corrugated shipping

carton and place on a flat surface taking care to not scratch

the plastic covers.

Inspect unit for concealed damage. If evident, notify

delivering carrier and file a claim against the same.

NOTE

Selecting/Preparing Counter Location

3. Select a location for the remote chiller system or carbonator

(if necessary), syrup pumps, CO

2

tank, product containers,

and water filter (recommended).

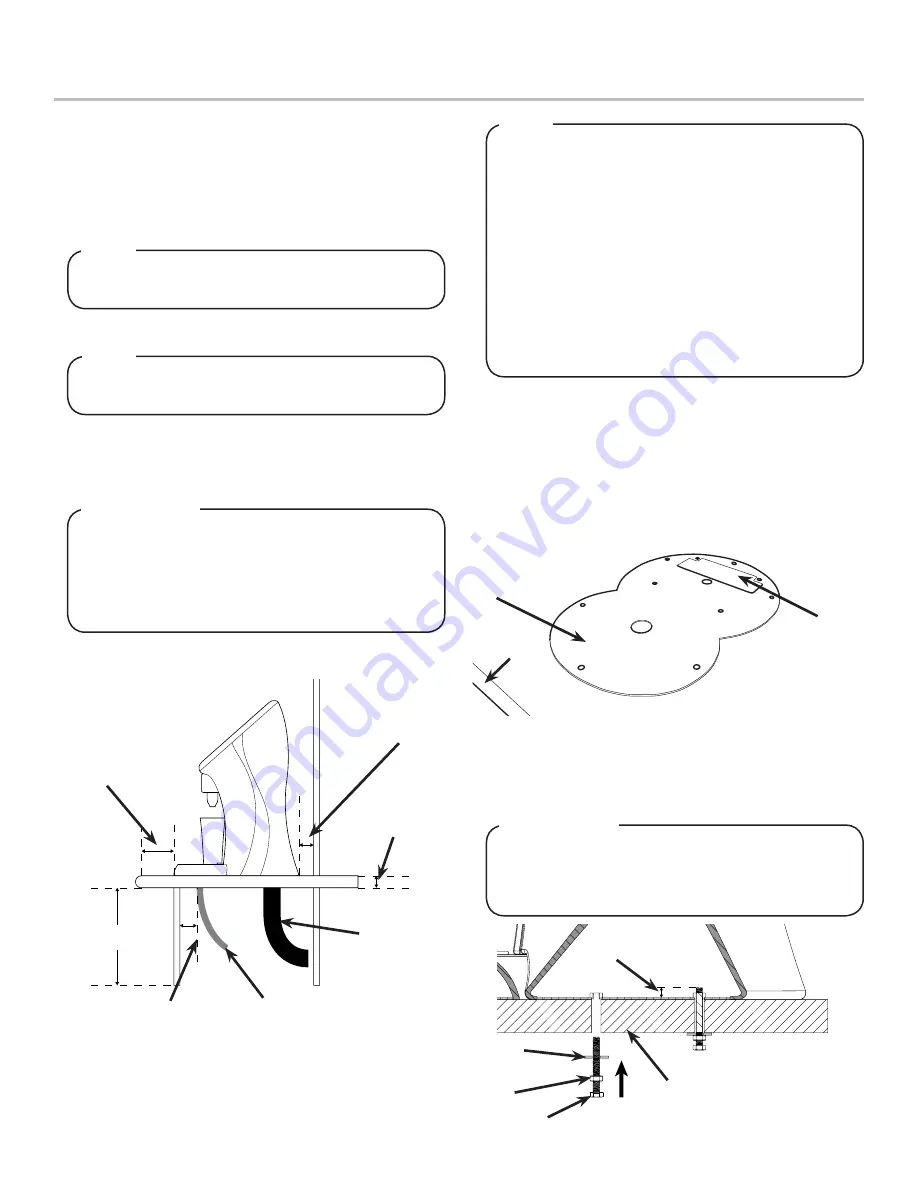

4. Using Counter Cutout Template provided, cut out required

opening for the drip tray and tower installation in the

designated dispenser location.

Dispenser/Chiller Installation

1. Carefully lift unit and using a screwdriver, separate the

mounting plate from the tower and drip tray.

2.

Remove the drain fitting from the drip tray. First, unscrew the

lower section then press firmly from the bottom to remove

the upper portion of the drain fitting.

3. Using the six (6) mounting screws provided, secure the

mounting plate to the counter top.

4. Using proper lifting techniques, lift the tower over the counter

top and slide the unit inlets and power cord through the

opening in the mounting plate/counter top.

5. Using the four (4) screws provided, connect/tighten tower to

mounting plate/counter top.

Inspect the counter location where the unit is to be

installed. Verify the selected counter is strong enough

to safely support the weight of the installed unit, after

the cutout for the unit is made. The ideal counter for

installation should measure at least 25 mm (1 inch)

thick.

!

ATTENTION

1. Select a location that is in close proximity to a properly

grounded electrical outlet, within 1.5 m (5 ft) of a drain, and

a water supply that meets the requirements shown in the

Specifications section found on page 2.

Min: 20 mm

Max: 225 mm

Min: 50 mm

Max: 42 mm

Max: 850 mm

A. Drain Tube

B. Inlet Tubes

A

B

To assure that beverage service is accessible to all

customers, Lancer recommends that counter height

and equipment selection be planned carefully. The

2010 ADA Standards for Accessible Design states that

the maximum reach height from the floor should be no

more than 1.2 meters (48 inches) if touch point is less

than 254 mm (10 inches) from the front of the counter,

or a maximum of 1.17 meters (46 inches) if the touch

point is more than 254 mm (10 inches) and less than

685 mm (27 inches) from the front of the counter. For

more information about the customer’s legal

requirements for the accessibility of installed

equipment, refer to 2010 ADA Standards for

Accessible Design - http://www.ada.gov.

NOTE

A. Mounting Plate

B. Counter Cutout

C. Counter Edge

A

B

C

2. Select a location that utilizes the clearances/space required

for installation.

The dispenser should only be installed in a location

where it can be overseen by trained personnel

NOTE

When attaching the tower to the mounting plate, make

sure the screws do not extend more than 20 mm (0.78

inches) from the top of the mounting plate. These could

damage the valves when installing the dispenser.

!

ATTENTION

E

A

B

C

A. Max. Height of 20 mm

B. Washer

C. Nut

D. Connecting Screw

E. Counter

D