12

CHECKING OUTFEED ROLLER

1. Place gauge block under outfeed roller. ( Fig.34)

2. Loosen nut no.(3) and screw no.(4), this will

allow for the outfeed roller to move upwards, or

downwards.

3. Make the roller touch the top of gauge block.

4. When adjustments have been finished, tighten

nut (3), and replace screw (4).

5. The same procedures apply for the other end.

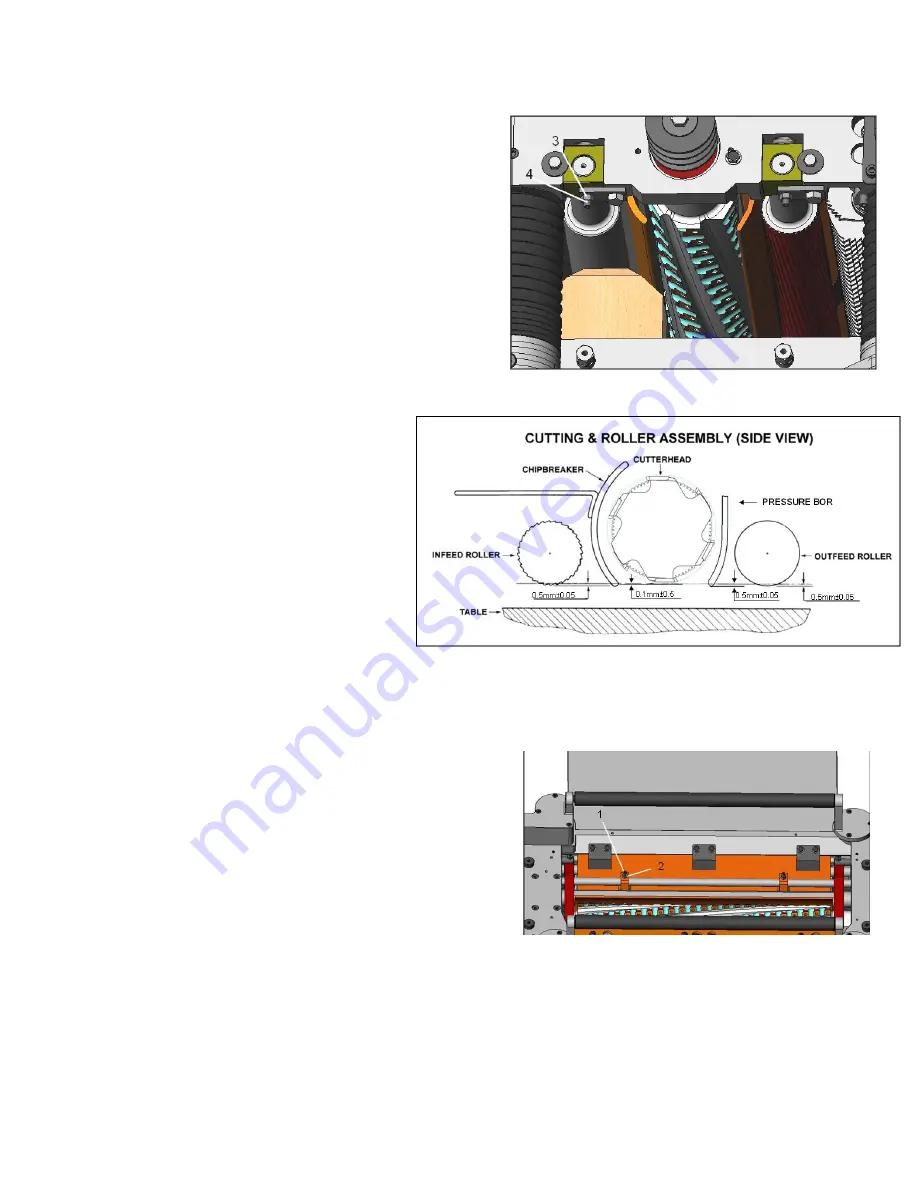

CHECK HEIGHT OF PRESSURE BAR

When adjusting pressure bar, the correct

position of wooden gauge and 0.2m/m

thickness gauge must be as shown in

(Fig. 35).

Adjustment

1. Loosen screw no.1 and nut no.2, turn the screw

to the right so that the pressure bar moves

upward. (Fig.36)

2. Place gauge block and 0.2m/m thickness

gauge under the cutterhead as shown in

(Fig.37).

3. Place gauge block under pressure bar.

4. Make pressure bar touch the top of the gauge

block.

5. Final, turn the screw (1) tightly, and replace the

nut (2).

Fig. 34

Fig. 35

Fig. 36