Mini-Combo

id

Page 5

persons. Attach run-off tube to T&P valve and

run tube within 6" (152mm) from floor. No

reducing couplings, valves, or any other type of

restriction is to be installed in this line. This run-

off tube must be installed to allow free and

complete drainage of both valve and run-off tube.

•

Filling Storage Water Tank

1.

Open hot water faucet in house to allow air

in the tank and in piping to escape.

2.

Open shut-off valve(s) in cold water supply

line.

3.

Open shut-off valve(s) in hot water supply

line.

2B. Heater Placement

The heater must be placed to provide clearances

on all sides for maintenance and inspection. Allow 4

inches on each side for piping access. There must also

be minimum distances maintained from combustible

surfaces. Figure 1 shows minimum clearance from

combustible surfaces. The Mini-Combo unit can be

installed in a closet, as long as the minimum

clearances are maintained. Special attention should be

paid to the air supply opening to the closet. Refer to

Table 1.

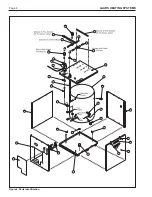

Figure 5. MCH Schematic.

Net Free Area — square inches

sq. cm

Model

Inside Air

Outside Air

MC50

100

645

15

97

MC75

100

645

20

129

MC100

100

645

25

161

MC125

125

806

32

206

Area indicated is for one of two openings: One at floor level and

one at the ceiling, so the total free area would be double the

figures indicated. Refer to Document 1080 for more information.

Table 1. Minimum Recommended Air Supply.

2C. Piping

• To prevent damage to the unit, all soldering is to

be done prior to assembling the cold and hot

water, and any other connections to the tank.

• Use suitable pipe dope or tape.

• Before piping the boiler to the heating system,

be sure to install the system check valve

(provided with the unit) onto the inlet (return)

tee of the boiler with arrow pointed downward

(see Figure 3).

• If anti-freeze is used in boiler system, local codes

may require a backflow preventer on cold supply

line. Use anti-freeze specifically intended for

hydronic heating system. Inhibited propylene

glycol is recommended.

WARNING

Do not use automotive or ethylene glycol anti-

freeze, or any undiluted anti-freeze. This can

cause severe personal injury, death or substantial

property damage.

If a backflow preventer, pressure reducing valve

or check valve is in cold water supply, install an

expansion tank on cold water supply line (see

Figure 4) to prevent normal thermal expansion from

repeatedly forcing open the T&P relief valve.

•

T&P relief valve's discharge piping must be

directed so that hot water flows away from all