Pag.3

INTRODUCTION AND GENERAL INSTRUCTIONS

Thoroughly read the instructions contained in this booklet because it gives important information regarding safety for installation, use and maintenance.

Keep this booklet in a safe and accessible place for further consultation.

This is a commercial appliance and must be installed and serviced only by La San Marco S.p.A. Authorised personnel

This machine must be used only for the purpose it was designed:

dispensing coffee, cappuccino and pouring hot water

Any other use is to be considered inappropriate and therefore dangerous.

The manufacturer declines all responsibility for damage caused by any improper, incorrect and unreasonable use of the machine.

The use of any electric appliance implies the observance of some fundamental rules.

More specifically:

-

do not touch the appliance with your hands or feet wet or damp

-

do not use the appliance with bare feet

-

do not pull the power cord to disconnect the plug from the power socket

-

do not leave the appliance exposed to the weather (rain, sun, frost)

-

do not let children or untrained persons use the appliance.

Before carrying out any cleaning and maintenance, disconnect the appliance from the power supply, pulling the plug from the power socket and turning off the

main switch.

In case of failure or malfunction turn the machine off and do not attempt to carry out any repairs or direct operations on the machine.

All repairs must be carried out in a La San Marco S.p.A Authorised Service Centre, using original spare parts only.

Failure to comply with the above recommendations will compromise the safety of the machine and the warranty conditions.

If this machine is no longer used, we recommend that it is made inoperative by disconnecting the power cord and water tube from the power supply, and all

potentially dangerous parts are made harmless, especially to protect children who might use the machine for their games.

INSTRUCTIONS FOR INSTALLATION

Installation must be carried out according to the manufacturer’s instructions.

An incorrect installation can cause damage to persons, animals or things; the manufacturer declines all responsibility for such situation.

After unpacking check that the machine is not damaged.

If in doubt, do not use the machine and contact a La San Marco S.p.A Authorised Service Centre.

All packing materials (plastic wrapping, polystyrene, nails, etc.) are potentially dangerous and must be kept out of children’s reach and disposed of in a safe

manner for the environment.

Before connecting the machine to the power supply make sure that the rating information of the machine correspond to that of the power supply: if the power

socket is not compatible with the plug of the machine (if supplied), replace the socket with a proper one, ensuring that the size of the cable is suitable for the

absorbed power of the machine. If you replace the power cord, use an H07RN-F cord again.

Make sure that the voltage rating of the machine corresponds to that of the power supply, and that the power supply is adequate to additional power absorption

of the machine.

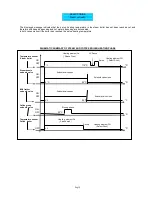

After installing the main switch and fuses (see annex), connect the power cord of the machine to the main switch according to the attached electrical diagram.

The use of adapters, multiple power boards and extension cords is not recommended.

If it is absolutely necessary, then use only single or multiple adapters and extension cords which comply with current safety regulations, ensuring also that the

electricity load capacity of the single adapters and extension cords and the maximum power rating of the multiple adapters is suitable.

The electrical safety of this machine can be guaranteed only if correctly connected to an efficient earth circuit as indicated by current electrical safety

regulations.

It is necessary to check this fundamental safety prerequisite, and in case of doubt, ask a professionally qualified technician to check the circuit.

The manufacturer declines all responsibility for any damage caused by failure to earth the machine.

In order to avoid any dangerous overheating, we recommend that the power cord be fully unwound.

The power cord of this machine must not be replaced by the customer.

In case of damage to the cord, contact exclusively a La San Marco S.p.A. Authorised Service Centre.

Do not leave the machine connected unnecessarily.

Turn off the main switch of the machine when not in use.

Do not cover the ventilation openings of the machine.

Place the machine at an adequate distance from walls, objects, etc.

The machine must be connected to a system with a water pressure, which is not greater than 5 bar. (Kg/cm

2

).

If the pressure is greater, a pressure reducer must be installed.

Install a water softener above the machine.

ENVIRONMENTAL CONDITIONS TO USE THE MACHINE

Environmental temperature:

5 – 45 °C (empty the hydraulic system in case of freezing)

Maximum humidity:

80% relative humidity

Water hardness:

5° eh, 7° dH, 13° Fh

SPECIAL INSTRUCTIONS FOR USE AND MAINTENANCE

For a correct functioning of the machine it is fundamental to comply with the manufacturer’s instructions, having qualified personnel to carry out ordinary

maintenance and to check all safety devices.

Avoid exposing hands or other parts of the body to the coffee dispensing spouts or to the hot water nozzle. The water from the nozzle is very hot and can cause

severe burns.

The water nozzle is very hot and therefore must be handled with care, holding it in the appropriate point.

Do not use the machine without water.

Do not leave the machine in rooms where the temperature is below zero °C or 32 °F without having first drained the boiler and the hydraulic circuit.

A softener needs to be used where the water is very hard and where the calcareous scaling is particularly extensive.

In any case, regularly check the boiler even where the water is not very hard, and if necessary, have the resistors and tubing descaled by specialised

technicians.

Failure to clean La San Marco S.p.A machines daily, especially for brewing unit and milk frother, using approved cleaning products and following

specified cleaning procedure will result in void warranty and service contract.

NOTE:

A)

THE REGISTRATION AND TECHNICAL DATA PLATE OF THE MACHINE IS BEHIND THE GROUND BIN.

B)

THE EQUIPMENT SHALL BE INSTALLED IN COMPLIANCE WITH FEDERAL, STATE AND LOCAL REGULATIONS.