IM-T-221B May,2018

DTC-A Clip-type Displacement Transducer INSTRUCTION MANUAL

Thank you for purchasing this KYOWA product. Before using it,

read this instruction manual carefully. Also, keep the manual within

easy reach so that you can refer to it whenever necessary.

1.

Calling the operator’s attention

Be sure to observe the accompanying precautions preserve the

performance of the instrument.

Caution

It is a precaution to operate properly.

2.

Handling precautions

Caution

Do not expand the space between the two beams or narrow it

even after they get in touch with the stoppers.

This product is exclusively designed for indoor use. When using

it, take care to avoid the direct rays of the sun, water, oil and

solvent.

Avoid measurement under vibration or impact.

Do not disassemble the displacement transducer.

3.

Installation

The mounting sections of the transducer (the respective heads of

the two beams) are so designed that they confirm with the ASTM

(American Society for Testing & Materials) Standards E399. Use

the transducer properly by referring to the standards.

3.1

How to mount

On the measuring area, prepare two opposed grooves to

accept the transducer, or mount the transducer by screwing or

bonding two opposed tips (TIP-10A) (available as options) to

the transducer mounting section.(See Fig.3.1.1 and 3.1.2)

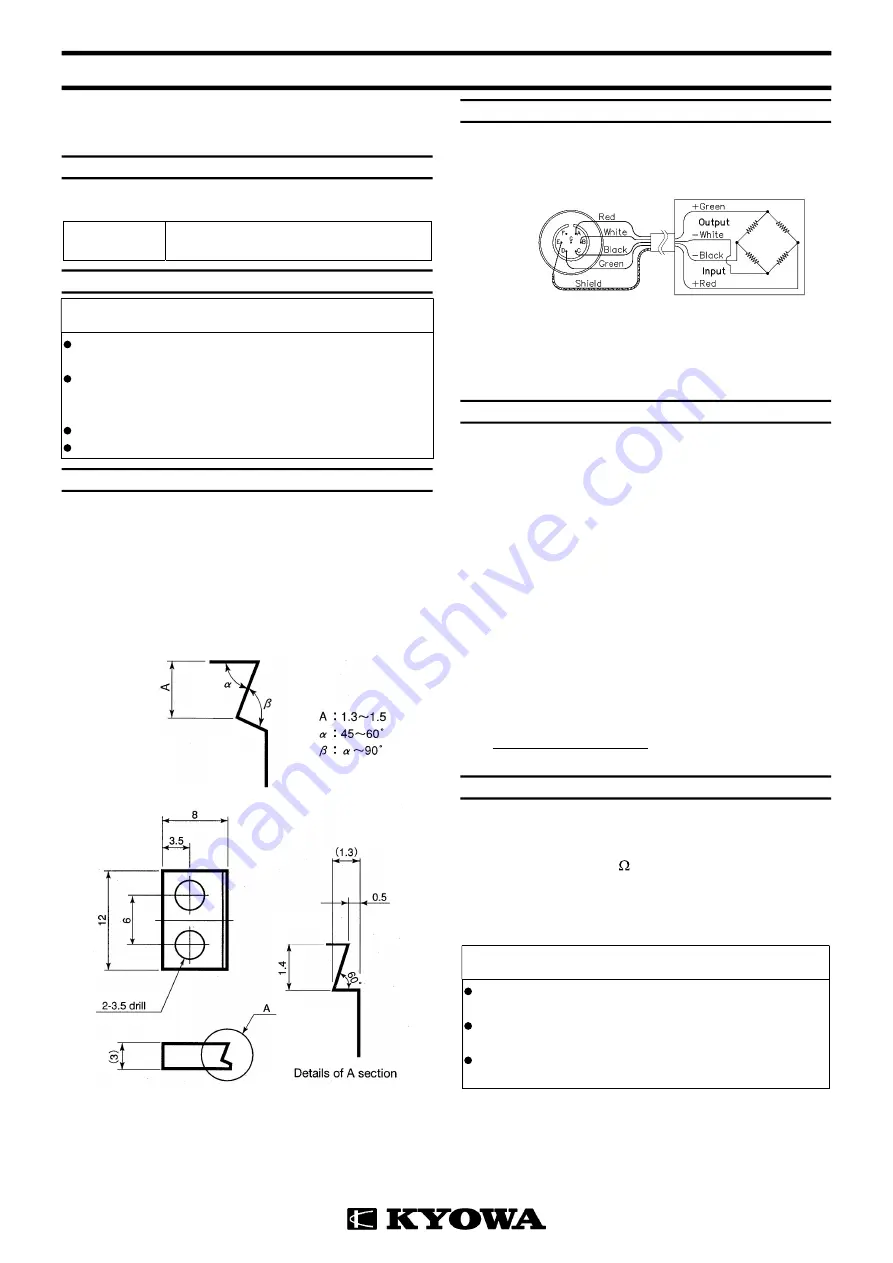

Fig.3.1.1 Configuration of groove on measuring object (ASTM Std.)

Fig.3.1.2 Configuration of tip (TIP-10A) (option)

When the two beams are free, the space between them is about

11mm. The measuring range is denoted by the space between the

mounting grooves. It is 4 to 9mm on DTC-A-5 and 8 to 10mm on

DTC-A-2. Fix the cable nearby the mainframe so that the mass of

the cable will not affect the transducer.

4.

Connection and measurement

4.1

Connect the transducer to a strain amplifier.

4.2

Perform connection as illustrated below when using an NDIS

connector.

Displacement transducer

(The shield wire is not connected to the mainframe.)

4.3

It is required to heat-run for 5 to 10 minutes before starting the

measurement.

4.4

Measurement values increase in the PLUS direction as space

grows between the beams.

5.

Conversion

5.1

Use the calibration constant described in the test data sheet to

convent a reading into a displacement value.

5.2

When a strain amplifier is in use, output reads in μm/m

equivalent strain (×10

-6

equivalent strain). Find a displacement

value corresponding to μm/m. Then, obtain a displacement

value through multiplication using the following equation.

Displacement value(mm)

=Strain amplifier's output (μm/m)

×Calibration constant (mm/1μm/m)

5.3

When using an amplifier of other type or a recorder, first find

the exact bridge exciting voltage applied. Second, find the

displacement value that corresponds to 1(μV) output voltage

against 1(V) bridge excitation voltage. Then, obtain the

displacement value through multiplication using the following

equation.

Displacement value(mm)

=

Bridge output voltage(μV)

×Calibration constant (mm/1μV/V)

Bridge excitation voltage(V)

6.

Storage and inspection

6.1

Avoid water, oil and dust on the displacement transducer.

6.2

If an abnormal initial value or reading appears, measure input

resistance, output resistance as well as insulation resistance

(which should be 100M or higher) between the main body

and red to green.

If abnormal resistance is found, the cause may be failure of the

sensing element. In this case, contact your KYOWA

representative for necessary inspection.

Caution

To measure insulation resistance, apply a voltage lower than

50V to the insulation resistance tester.

When storing the transducer, be sure that it is free from

displacement.

Avoid storing the transducer where it is exposed to especially

high or low temperature or much dust.