About the Cutter Head with Optional Side Drill Assembly

KVAL Operation Manual

5-10

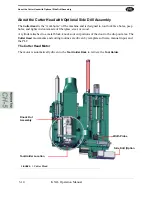

About the Cutter Head with Optional Side Drill Assembly

The

Cutter Head

is the “workhorse” of the machine and is designed to rout lock face holes, peep

holes, and lights in doors made of fiberglass, steel, or wood.

A cylinder attached to a metal block, knocks out cut portions of the door to the drop out area. The

Cutter Head

movements and cutting routines are driven by template software, manual input, and

the PLC.

The Cutter Head Motor

The motor is automatically driven to the

Tool Holder Rack

to retrieve the

Tool Holder

.

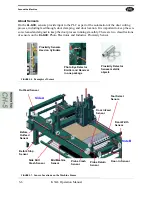

Tool Holder Location

Knock-Out

Assembly

Side Drill (Option

Width Probe

FIGURE 5- 1.

Cutter Head

Summary of Contents for DL-NCD

Page 10: ...KVAL DL NCD Operation Manual Table of Contents ...

Page 28: ...How to Download the Service Application KVAL Operation Manual 1 18 ...

Page 30: ...Safety Sign Off Sheet KVAL Operation Manual 1 20 ...

Page 62: ...About the LiteCutout Feature Detail KVAL Operation Manual 2 32 ...

Page 94: ...Appendix About Backing up the Data KVAL Operation Manual 3 32 ...

Page 118: ...Appendix Servo Motor Drive Assembly Locations KVAL Operation Manual 4 24 ...

Page 139: ...About the Electrical Panels KVAL Operation Manual 5 21 I ...

Page 142: ......

Page 143: ......