FC243RGII

60

9. - Optional equipment

KN041BGB A

Mower conditioner

9.5

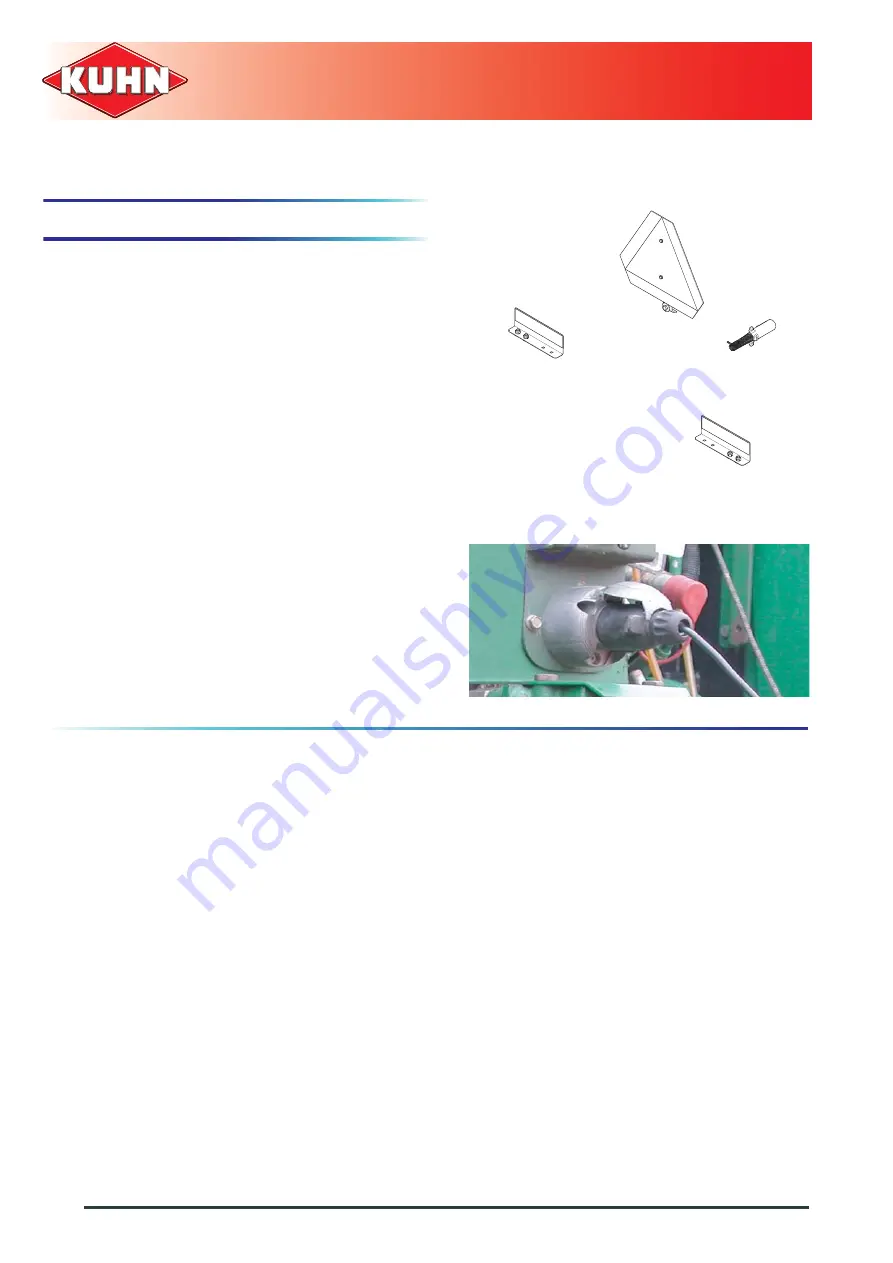

USA signalling equipment

Kit no. 1046280

9.5.1 Coupling and uncoupling

Electrical connection

- Connect 7-pin plug to the tractor.

Parking

- Disconnect and store 7-pin plug in its holder.