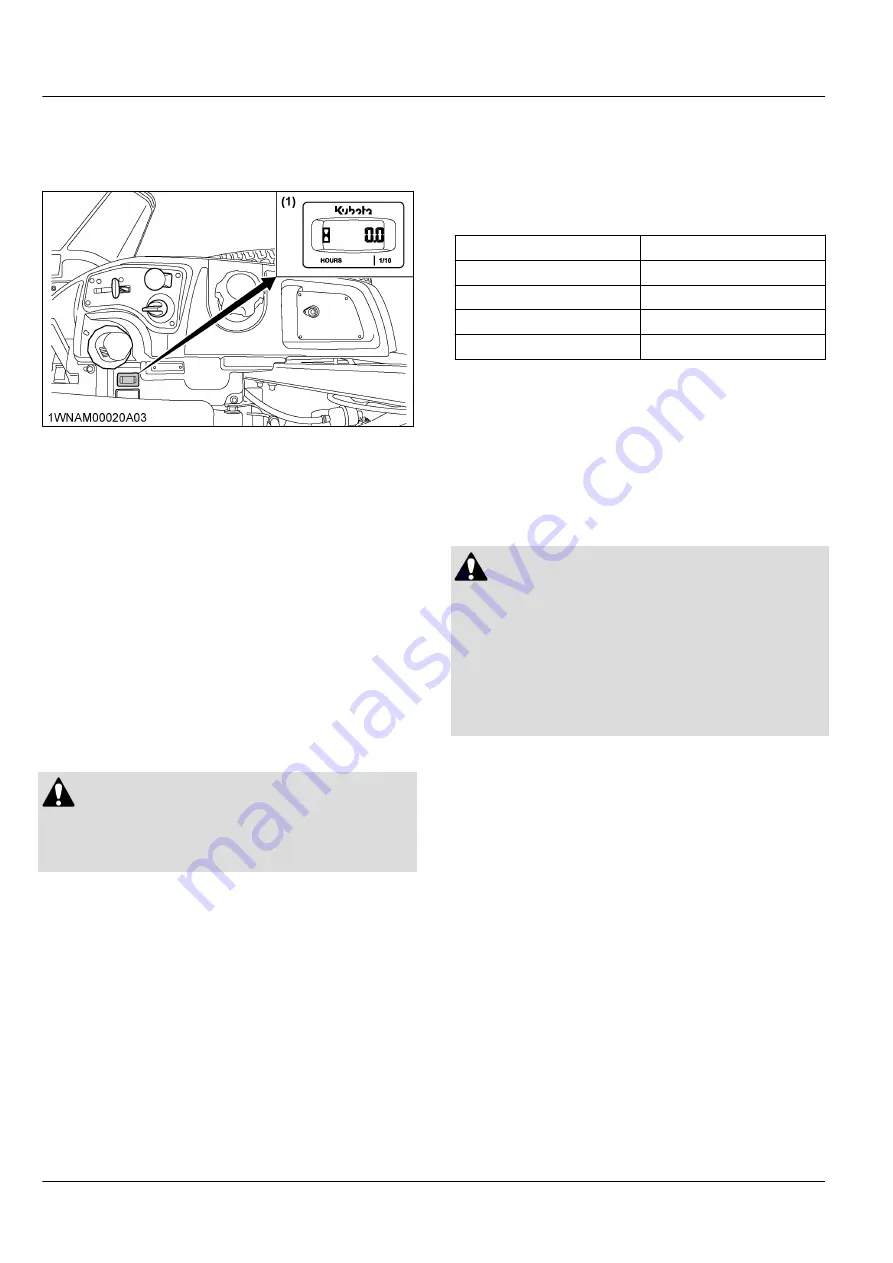

2. Hour meter

This meter indicates the number of hours the engine

has run.

(1) Hour meter

COLD WEATHER STARTING

If the ambient temperature is below 0

℃

(32

℉

) and the

engine is very cold, start it in the following manner:

1. Place the throttle lever to the

“CHOKE”

position.

2. Place the throttle lever midway between the

“SLOW”

and the

“FAST”

positions.

3. Turn the key switch to the

“START”

position.

a. Operate the starter 5 seconds.

b. If the engine does not start, wait 10 seconds.

c. Repeat this procedure until the engine starts.

4. When the engine starts, release the key to the

“ON”

position.

WARMING UP THE ENGINE

WARNING

To avoid serious injury or death:

• Be sure to apply the parking brake during

warm-up.

For 5 minutes after the engine start-up, allow the

engine to warm up without applying any load. This is to

allow oil to reach every part of the engine. If load is

applied to the engine without this warm-up period,

problems such as seizure, breakage or premature wear

may appear.

1. Warm-up and transmission oil in

the low temperature range

Hydraulic oil serves as transmission oil. In cold weather

conditions, the oil may be cold with increased viscosity.

This can cause delayed oil circulation or abnormally

low hydraulic pressure for some time after engine start-

up. This, in turn, can create problems with the hydraulic

system.

To prevent this from happening warm up the engine at

about 50% of rated rpm according to the following

table.

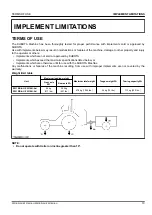

Ambient temperature

Warm-up time requirement

Higher than 0

℃

(32

℉

)

Approximately 5 minutes

-10 to 0

℃

(14 to 32

℉

)

5 to 10 minutes

-20 to -10

℃

(-4 to 14

℉

)

10 to 15 minutes

Below -20

℃

(-4

℉

)

More than 15 minutes

IMPORTANT :

• Do not operate unless the engine is well

warmed up. If operation is attempted while the

engine is still cold, the hydraulic mechanism

will not function properly and its service life will

be shortened.

JUMP STARTING

WARNING

To avoid serious injury or death:

• Keep cigarettes, sparks, and flames away from

the battery.

• If the machine battery is frozen, do not jump

start the engine.

• Do not connect the other end of the negative

jumper cable to the negative terminal of the

machine battery.

When jump starting the engine, observe the following

instructions to start the engine safely:

1. Bring a helper vehicle with a battery of the same

voltage as the disabled machine within easy cable

reach.

IMPORTANT :

• The vehicles must not touch.

2. Apply the parking brakes of both vehicles and put

the shift levers in the neutral position. Shut the

engine off.

3. Put on safety goggles and rubber gloves.

4. Ensure that vent caps are securely in place (if

equipped).

5. Attach the red clamp to the positive (red, (+) or

pos.) terminal of the dead battery and clamp the

other end of the same cable to the positive (red, (+)

or pos.) terminal of the helper battery.

6. Clamp the other cable to the negative (black, (-) or

neg.) terminal of the helper battery.

OPERATING THE ENGINE

CHECK DURING OPERATING

26

Z231BR-AU,Z231KH-AU,Z251BR-AU,Z251KH-AU

Summary of Contents for Z231BR-AU

Page 7: ...4 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 13: ...SAFETY LABELS SAFE OPERATION 10 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 14: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 11 ...

Page 15: ...SAFE OPERATION 12 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...

Page 16: ...SAFE OPERATION Z231BR AU Z231KH AU Z251BR AU Z251KH AU 13 ...

Page 85: ...wheels 38 82 Z231BR AU Z231KH AU Z251BR AU Z251KH AU ...