KTR Kupplungstechnik

GmbH

D-48407 Rheine

B o W e x - E L A S T I C

®

Operating-/Assembly Instructions

Design 065 (HEW1 and HEW2)

KTR-N

sheet:

edition:

40114 E

11

4

Gezeichnet:

08.04.04 Sha/Hk

Ersatz für:

KTR-N vom 01.12.99

Schutzvermerk

ISO 16016 beachten.

Geprüft:

08.04.04 Sha

Ersetzt durch:

5 Enclosure A

Hints and instructions regarding the use in

hazardous areas

5.6 Starting

The distance between the cover and the rotating parts must be at least 5 mm.

The cover must be electrically conductive and be included in the equipotential bonding. Bellhousings made from

aluminium and damping rings (NBR) can be used as connecting element between pump and electro motor if the

magnesium part is below 7,5 %. The cover may only be taken off after having stopped the unit.

During operation, please pay attention to

•

strange running noises

•

occurring vibrations.

!

C A U T I O N !

If you note any irregularities at the coupling during operation, the drive unit must be turned

off immediately. The cause of the breakdown must be found out with the table

„Breakdowns“ and, if possible, be eliminated according to the proposals. The possible

breakdowns mentioned can be hints only. To find out the cause all operating factors and

machine components must be considered.

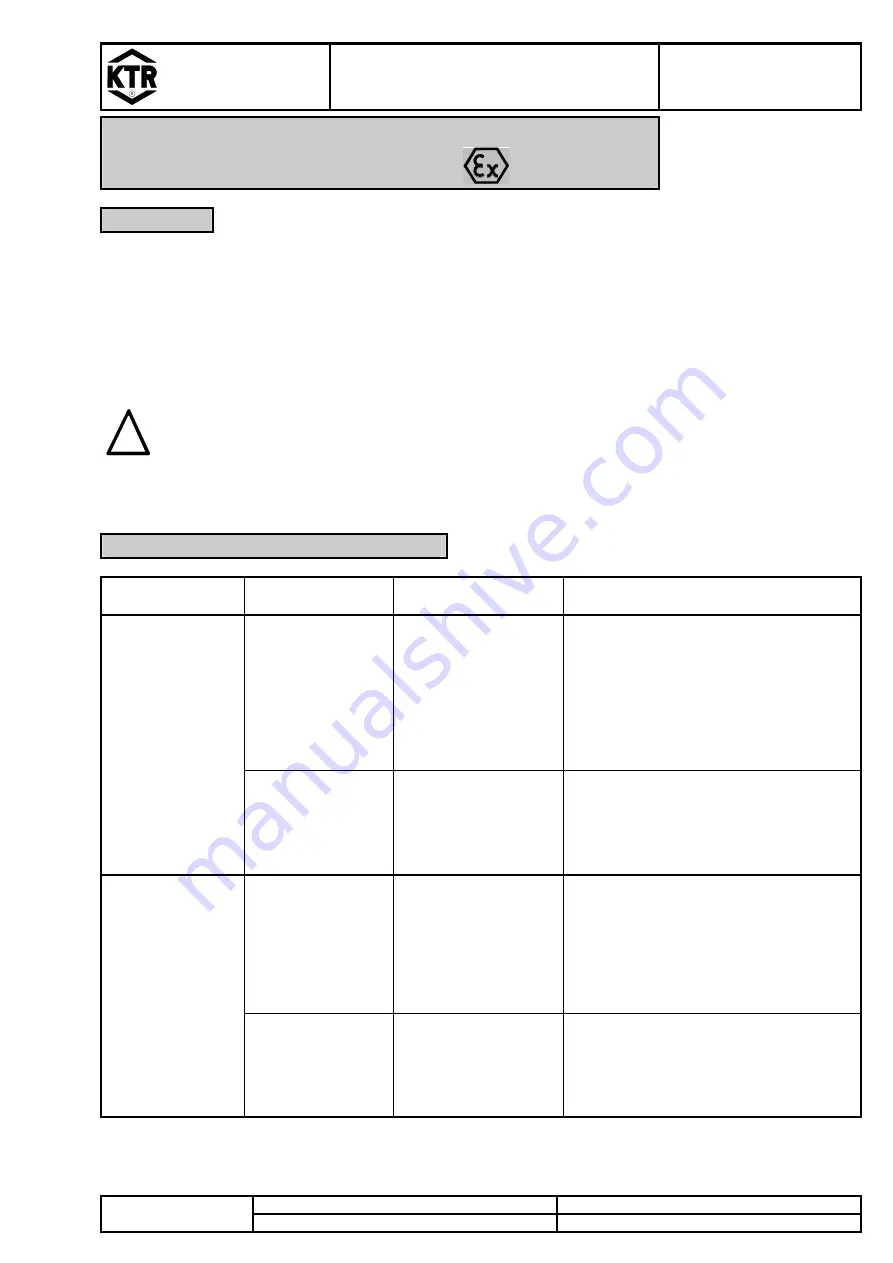

5.7 Breakdowns, Causes and Elimination

breakdowns causes

danger hints for

hazardous areas

elimination

misalignment

friction at the

toothing of the

elastomer part

danger of ignition due

to hot surfaces

1) put the unit out of operation

2) eliminate the reason for the

misalignment (e. g. loose foundation

bolts, break of the engine fixing, heat

expansion of unit components, change

of the assembly dimension E of the

coupling)

3) checking of wear see under point

Control

change of the

running noises

and / or occurring

vibrations

loose screws for

axial securement of

hubs

danger of ignition due

to hot surfaces

1) put the unit out of operation

2) check alignment of coupling

3) tighten the screws to secure the hubs

and secure against self-loosening

4) checking of wear see under point

Control

break of the

elastomer part /

toothing due to

overload

---

1) put the unit out of operation

2) disassemble the coupling and remove

rests of the elastomer part

3) check coupling parts and exchange

damaged coupling parts

4) insert elastomer part, assemble coupling

parts

5) find out the reason of overload

break of the

elastomer part

operating

parameters do not

correspond to the

performance of the

coupling

---

1) put the unit out of operation

2) check the operating parameters and

select a larger coupling (consider

installation space)

3) assemble new coupling size

4) check alignment