RWCP, RWCN

12

Type of grease:

We recommend using lytic-based lubrication grease with

antioxidant additives, of consistency 3 in line with DIN-51502

K3K.

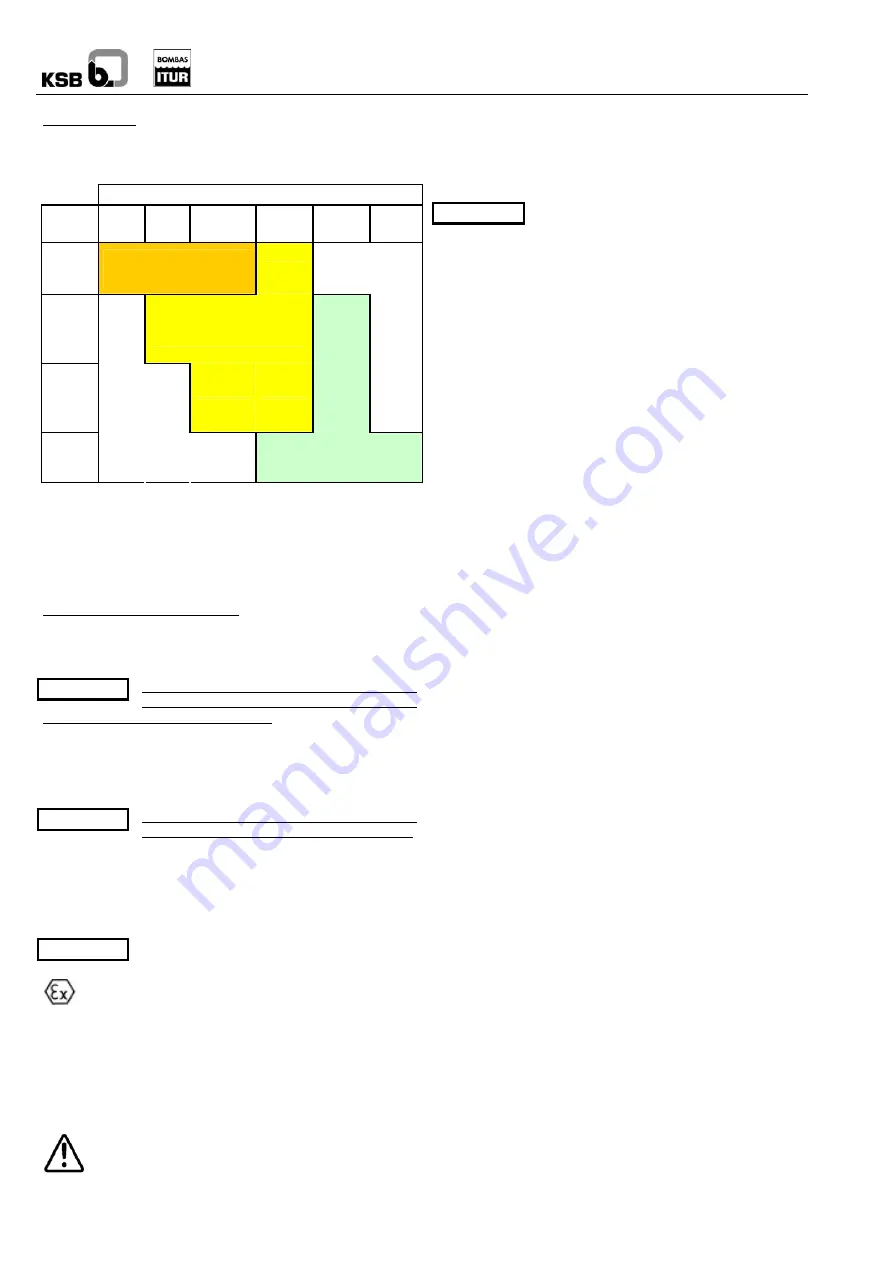

MOTOR

FRAME

PUMP

80 to

90 S/L

100L

to

112M

132 S/M to

180 M/L

200L to

225 S/M

250M to

280 S/M

315S/M

50/160

50/200

65/200

Bearing: 2 x 7307

Re-lubrication: 17g

Re-filling: approx. 25g

65/315

80/250

100/250

100/315

Bearing: 2 x 7310

Re-lubrication: 30 g

Re-filling: approx. 70g

80/400

100/400

150/315

200/315

125/500

150/500

200/400

Bearing: 2 x 7314 + 6314

Re-lubrication: 80 g

Re-filling: approx.180g

FRICTION BEARINGS:

The friction bearings are found in the cover of pumps (always)

and also in the case of double/triple intermediate pipe pumps,

in the intermediate couplings in the intermediate couplings

These bearings must always be lubricated and cooled. There

are three types of lubrication:

1. Lubricated with pumping fluid: If the pumped fluid is clean

(without particles in suspension) and non-aggressive, the

friction bearings are lubricated with the pumped fluid.

Lubricant is not required.

2. Lubricated with external fluid PUMPS

WITH EXTERIOR AUXILIARY

CONNECTION IN THE BASE PLATE: For this purpose there

is an adapter in the base plate which the customer will inject

with clean water or another fluid compatible with the pumped

fluid at a pressure of approximately 3 kg/cm

2

(manometer).

The flow necessary per bearing can be seen in the chart in

annex

3. Lubricated WITH AUTOMATIC

LUBRICATION PUMP IN THE BASE PLATE:

The auxiliary pump has a container with grease to lubricate

the bearings. We recommend using lytic-based lubrication

grease with antioxidant additives, of consistency 2, in line with

DIN-51502 class K2K. The auxiliary pump does not require

maintenance, although the container must contain grease at

all times.

The automatic pump container must be filled

with grease before starting up.

Excessive wear of the bearings may cause friction of

the metal parts, thus locally increasing the

temperature. The pump shall have forced refrigeration from

the pumping fluid if it is clean, or with exterior lubrication of

clean liquid if the pumping fluid is dirty. In the latter case, the

plant operator must maintain a permanent input of clean liquid

to ensure the correct maintenance of the bearing refrigeration

fluid and conducts.

7.3 Emptying/Drainage

The emptying and drainage of pumps used to expel

liquids which are a health hazard must be carried out

in such a way as there is no risk to people or to the

environment, in line with legislation. If necessary, use

protective clothing and mask.

7.4 Dismantling

7.4.1 Fundamental

instructions/observations

Before dismantling, ensure the pump cannot

be started up.

Note

The suction and impulsion valves must be closed.

The pump frame must have returned to environmental

temperature.

The pump frame must be emptied.

Comply with all safety measures in accordance with

When working on the motor, also take into account the rules

and instructions of the manufacturer.

7.4.2 Coupling

Motor pump coupling

- Release

the

motor attachment screws and remove the

motor along with the male coupling.

-

The rubber plugs can then be extracted from the female

coupling.

-

If you need to release the coupling, use an extractor.

Never bang in order to extract, as this may cause serious

damage to the bearings.

Intermediate coupling

-

Release the cover halves on both ends of the coupling.

-

Uncouple the two shafts by gently and uniformly banging

the coupling with a plastic hammer.

7.4.3 Mechanical

seal (when fitted)

In order to have access to the mechanical seal, it is necessary

to dismount almost the whole pump as described in point

(until the seal dismantling section is reached). Once this

process is complete:

Note

-

Release the joining screws between fixing ring and cover

and slide the fixing ring carefully together with the

drainage sleeve along the shaft towards pump side until

the ring is taken out.

- Release the keep pins from the rechangable bushing

and slide this together with the mobile part of the

mechanical seal along the shaft towards pump side until

bushing is removed.

Note

- Slide (towards pump side) and remove carefully the

assembly composed by mechanical seal cover and the

static part of the mechanical seal. Once this assembly is

removed proceed to dismantling of the mechanical seal.

Note

- Release the joining Allen screws between cover and

mechanical seal cover.

-

Release the static part of the seal pushing from top side

of the mechanical seal cover taking care for not to touch

the rubbing face of the seal.

7.4.4

Packing (where fitted)

In order to access the seal, first dismount almost all the pump

as described in point - (until the packing dismantling section is

reached). Once this process is complete:

-

Release the packing gland.

-

Slide and extract the cover with the packing along the

shaft towards the pump side.