Submersible motor pumps (100 mm)

4

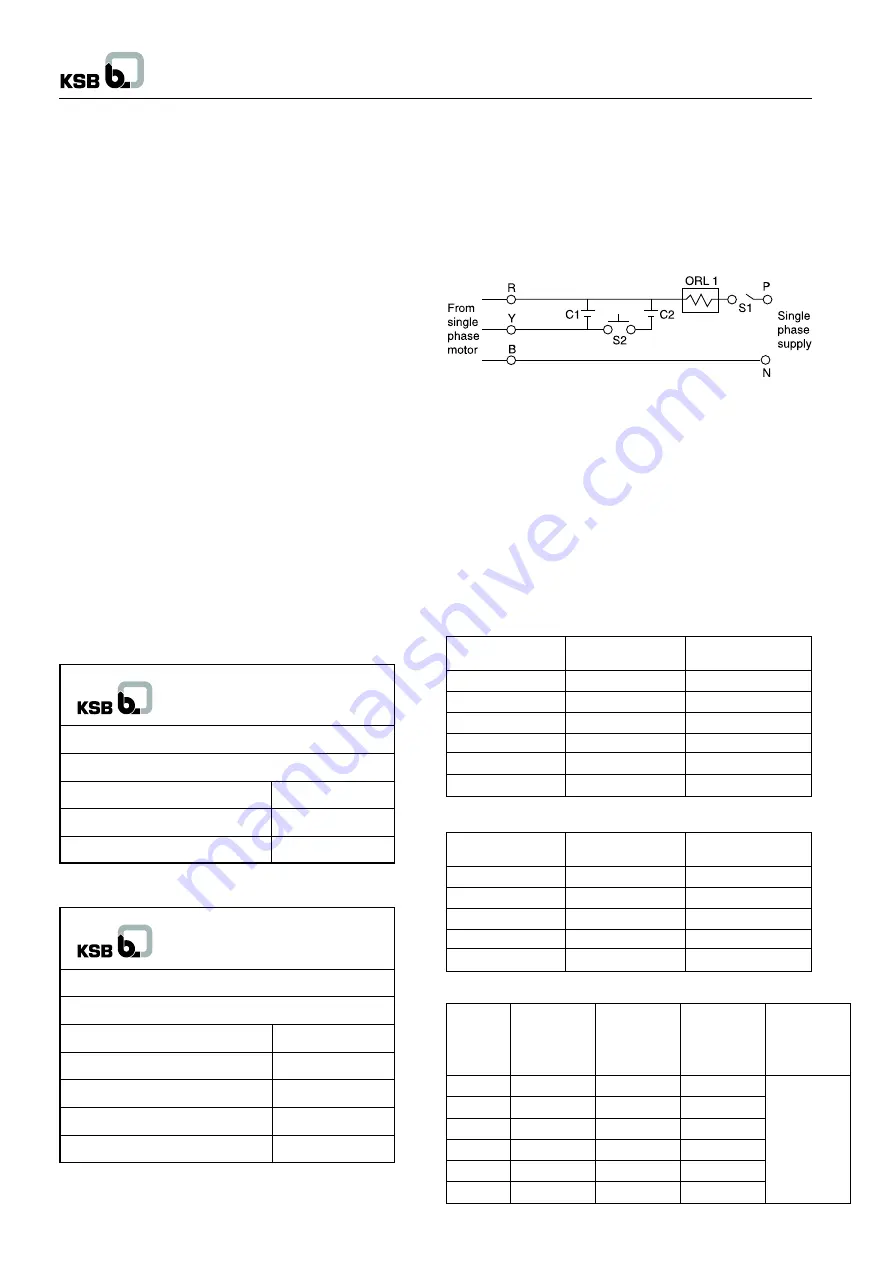

R : Red color wire

C2 : Starting capacitor

B : Blue color wire

C1 : Running capacitor

Y : Yellow color wire

ORL 1 : Overload relay

S1 : On-off main switch

P : Phase

S2 : Starting push button

N : Neutral

Caution :

S2 - Starting push button should be pressed max. for 5 sec. In

case if the motor does not start, continuous operation of this

button may lead to burning the motor.

Capacitor details

C1 : Running capacitor :

Polypropylene (440 V)

C2 : Starting capacitor :

Electrolytic (230 V)

UMA I (S) 100

Motor capacity

Run Capacitor

Start Capacitor

kW

µµµµµ

F

µµµµµ

F

0.37

20

60

0.55

20

80-100

0.75

36

80-100

1.1

30

100-120

1.5

30

100-120

2.2

100

120-150

valve body and the vertical pipe line. This precaution will help

even in case of GI riser piping.

2.3.4 Installation of water level guard

Install a water level guard for dry running protection to avoid the

damage of pump unit in case of water level fluctuations.

2.3.5 Protection against electric shock

Submersible motors are provided with external earthing plug at

upper bearing body as a standard. A three-cored cable is led out

of the motor. The operator / user shall be responsible for proper

connection of the earthed conductor and of control unit at site.

2.3.6 Fixing the power supply cable to the riser pipe

During installation of pump into the bore well, power supply cable

should be fixed to the raiser pipe by means of cable clips at a

distance of approx. 3 m immediately after the flange or coupling

of the pipe.

2.3.7 Verification of power line with respect to

motor design

Verify the voltage and frequency of main supply with the data

given on the motor’s nameplate.

If it is not matching then consult with concerned electrical

authority.

Ensure that the main power supply is stable.

Typical examples of name plate :

Pump name plate :

Motor name plate :

For operational values refer the nameplate attached to the pump

unit.

2.3.8 Trip circuit for over current

A temperature compensated over current relay has to be provided

in the operational electrical circuit.

2.4

Starting mode

2.4.1 For single-phase motor

Single-phase motor connection diagram of starting method for

DOL is :

UMA (S) 100

Motor capacity

Run Capacitor

Start Capacitor

kW

µµµµµ

F

µµµµµ

F

0.5

25

100

0.8

25

100

1.25

36

120

1.5

50

120

2.2

50

200

XUMA (S) 100

Motor

Run

Start

Run

Start

Capacity Capacitor

Capacitor

Capacitor

Capacitor

kW

µµµµµ

F

µµµµµ

F

µµµµµ

F

µµµµµ

F

(> 180 Volt) (> 180 Volt) (< 180 Volt) (< 180 Volt)

0.37

20

60 - 80

30

0.55

30

80 - 100

30

0.75

36

80 - 100

50

1.1

50

100 - 120

50

1.5

50

100 - 120

100

2.2

100

120 - 150

120

Value to be

enhance as

per actual

site

voltage

condition

KSB PUMPS LTD.

Type

:

CORA 100 1C/20

Sr. No.

: -----

Q

: 2.1

m

3

/hr

Year

: 2010

H

: 48

mtrs

kW

: 0.75

N

: 2800

rpm

Ex.

:

KSB PUMPS LTD.

Type

:

UMA I ( S ) 100 - 0.75 / 22

Sr. No.

: ----

Voltage

: 220

V

Amp

: 11.0

kW / HP

: 0.75 / 1.0

Conn

: ---

Speed

: 2800

rpm

Year

: 2010

Run Capacitor : 36 uF

440 V

Hz

: 50 ± 3

Start Capacitor : 50 uF

230 V

AC

: 1 Ph

+ 6

- 15