APORIS - 12

6.6 Handling

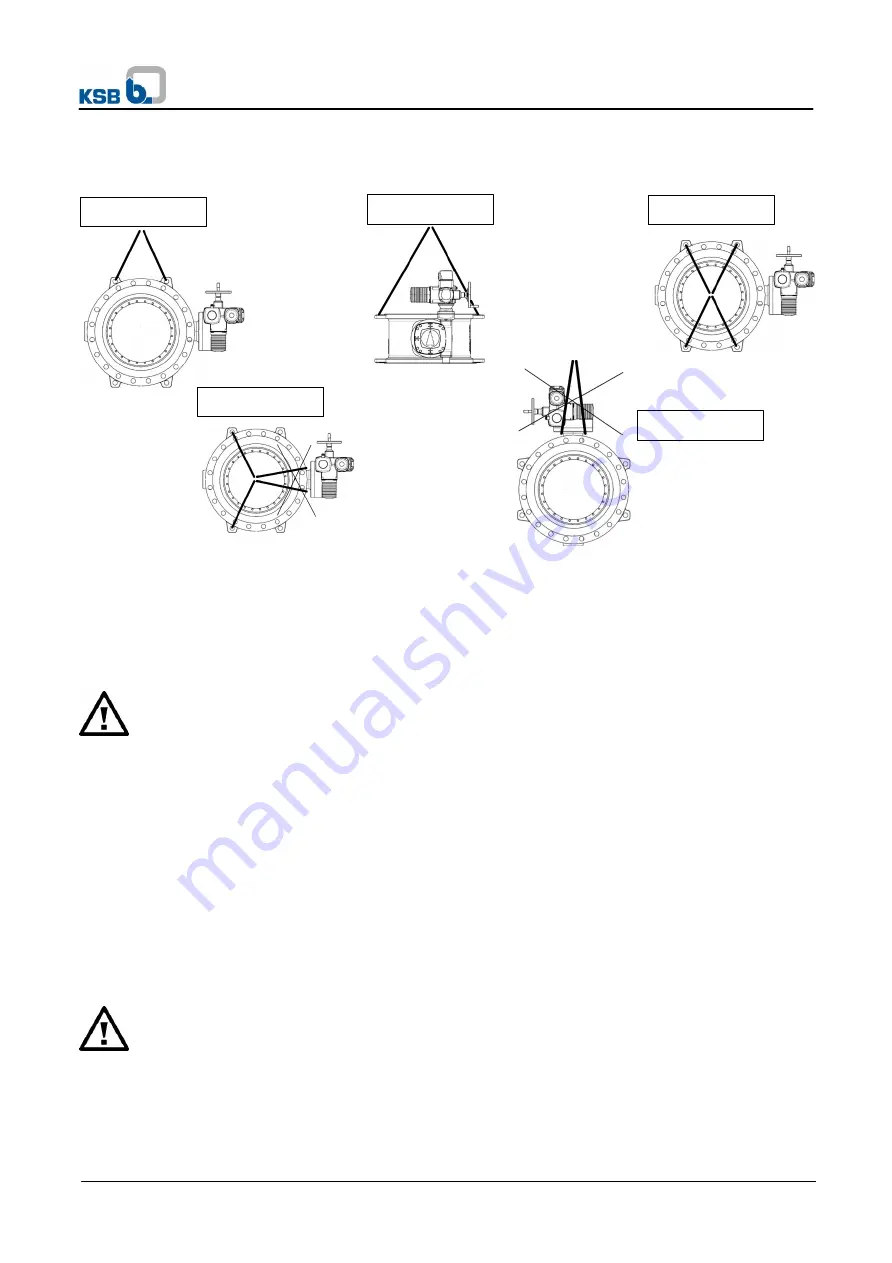

Handling means may be necessary to install large sizes valves.

They must be used as shown.

7

Commissioning/Decommissioning

7.1 Commissioning

7.1.1 General

Prior to commissioning the valve, the pressure, temperature and material data stated on the valve should be compared to

the actual operating conditions in the piping system to check whether the valve can withstand the loads occurring in the

system.

Possible pressure surges (water hammer) must not be exceed the highest admissible pressure. Adequate

precautions should be taken. In new pipe systems and especially after repair work, the system should be flushed with the

valves fully open to remove solids, e.g. weld beads, which may damage the seats.

7.1.2 Operation

The position of the disc is indicated by the pointer of the actuator or by handle lever. The valves are closed by turning in the

clockwise direction (top view) and opened in the counter clockwise direction.

7.1.3 Functional Check

The following functions should be checked: before commissioning, the shut-off-function of the valves should be checked by

repeated opening and closing

.

7.1.4 Actuated valves

Adjustable end stops and torque limiter are pre-adjusted in factory. The customer may have to complete the adjustment on

site during the commissioning, if necessary.

Verify gears and actuators Operating Manual issued by its manufacturer

7.2 Decommissioning

During extended shutdown periods, liquids liable to change their condition due to polymerization, crystallization,

solidification etc. must be drained from the piping system. If necessary, the piping system should be flushed with the valves

fully open.

Correct

Correct

Correct

FORBIDDEN

FORBIDDEN