DANGER

Incorrect screws

Explosion hazard!

▷

Always use the original screws for assembling an explosion-proof pump set.

▷

Never use screws of different dimensions or of a lower property class.

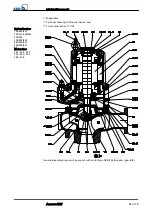

7.5.4 Performing a leak test

After reassembly the mechanical seal area/lubricant reservoir must be tested for

leakage. The lubricant filler opening is used for leak testing.

Observe the following values for leak testing:

▪

Test medium: compressed air

▪

Test pressure: 0.8 bar (max.)

▪

Test period: 2 minutes

P

0.5 bar

Fig. 34: Screwing in the testing device

1. Unscrew and remove the screw plug and joint ring of the lubricant reservoir.

2. Tightly screw the testing device into the filler opening for the lubricant.

3. Perform the leak test to the above conditions.

The pressure must not drop during the test period.

If the pressure does drop, check the seals and screwed connections.

Then perform another leak test.

4. Once the leak test has been successful, fill in the lubricant. (

7.5.5 Checking the connection of motor/power supply

Once the reassembly has been completed, carry out the steps described in (

7.6

Tightening torques

Table 25: Tightening torques

Thread

Tightening torque [Nm]

M 5

4

M 6

7

M 8

17

M 10

35

M 12

60

M 16

150

M 20

290

M 24

278

7 Servicing/Maintenance

54 of 78

Amarex KRT

Summary of Contents for Amarex KRT

Page 77: ......