All bolted/screwed connections closing off the flameproof enclosure must be secured

with a thread-locking agent (Loctite Type 243).

7.5.2 Reassembling the pump section

7.5.2.1 Installing the mechanical seal

Observe the following points to ensure trouble-free operation of the mechanical

seal:

▪

Only remove the protective wrapping of the contact faces immediately before

assembly takes place.

▪

Make sure the surface of the shaft is absolutely clean and undamaged.

▪

Before the actual installation of the mechanical seal, wet the contact faces with a

drop of oil.

▪

For easier installation of bellows-type mechanical seals, wet the inside diameter

of the bellows with soapy water (no oil).

▪

To prevent any damage to the rubber bellows, place a thin foil (thickness

approximately 0.1 to 0.3 mm) around the free shaft stub.

Slip the rotating assembly over the foil into its installation position.

Then remove the foil.

✓

The shaft and rolling element bearings have been properly fitted in the motor.

1. Push drive-end mechanical seal 433.01 onto shaft 210 and secure it with taper

lock ring 515 or circlip 932.03.

2. Insert O-rings 412.04 or 412.35 and 412.15 or 412.11 into discharge cover 163,

and press them into bearing bracket 330 as far as they will go.

3. Push pump-end mechanical seal 433.02 onto shaft 210.

For special mechanical seals with covered spring, tighten the socket head cap screw

at the rotating assembly before fitting the impeller. Observe installation dimension

"A".

Table 23: Installation dimension "A"

Pump size

Installation dimension "A"

[mm]

40-250, 80-250, 100-250

29

80-251, 100-251, 150-251, 80-315/-316,

150-315, 200-315/-316, 100-316

38.5

100-401, 150-401, 151-401, 200-330,

200-400, 250-400/-401, 300-400/-401

48.3

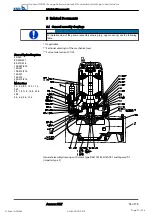

7.5.2.2 Fitting the impeller

NOTE

For bearing brackets with tapered fit make sure that the tapered fit of impeller and shaft

is undamaged and installed free from grease.

A

Fig. 25: Installation

dimension "A"

7 Servicing/Maintenance

Amarex KRT

47 of 74

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 49 of 96