5 Installation/Dismantling

18 of 32

4K / 4KD

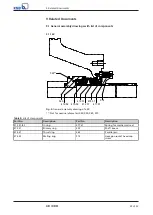

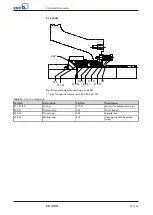

Dismantling steps for a double mechanical seal

1.

Separate the pipes of the barrier/buffer fluid supply system from seal cover

471.01.

2.

Undo the hexagon head bolts at the bearing bracket lantern.

3.

Position the spacer so as to support shaft sleeve 523.

4.

Carefully pull casing cover 161 with seal cover 471.01 and the entire mechanical

seal in tandem arrangement off the bearing bracket lantern / pump shaft. Place

them down in a horizontal position.

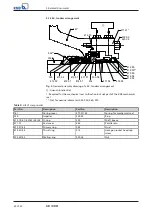

5.

Undo nuts 920.02 of studs 902.02 at seal cover 471.01. Remove the seal cover

with O-ring 412.15.

6.

Remove mating ring 475.55 and O-ring 412.55 from seal cover 471.01.

7.

Slide primary ring 472.54 with O-ring 412.54 as well as spring 477.54 and disc

500.54 off shaft sleeve 523.

8.

Undo hexagon socket head cap screws 914. Remove springs 477.51 and thrust

ring 474.51.

9.

Lift casing cover 161 and turn it so that primary ring 472.51 and O-ring 412.51

can be removed.

10.

Remove primary ring 472.51 and O-ring 412.51 from the shaft sleeve.

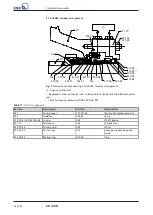

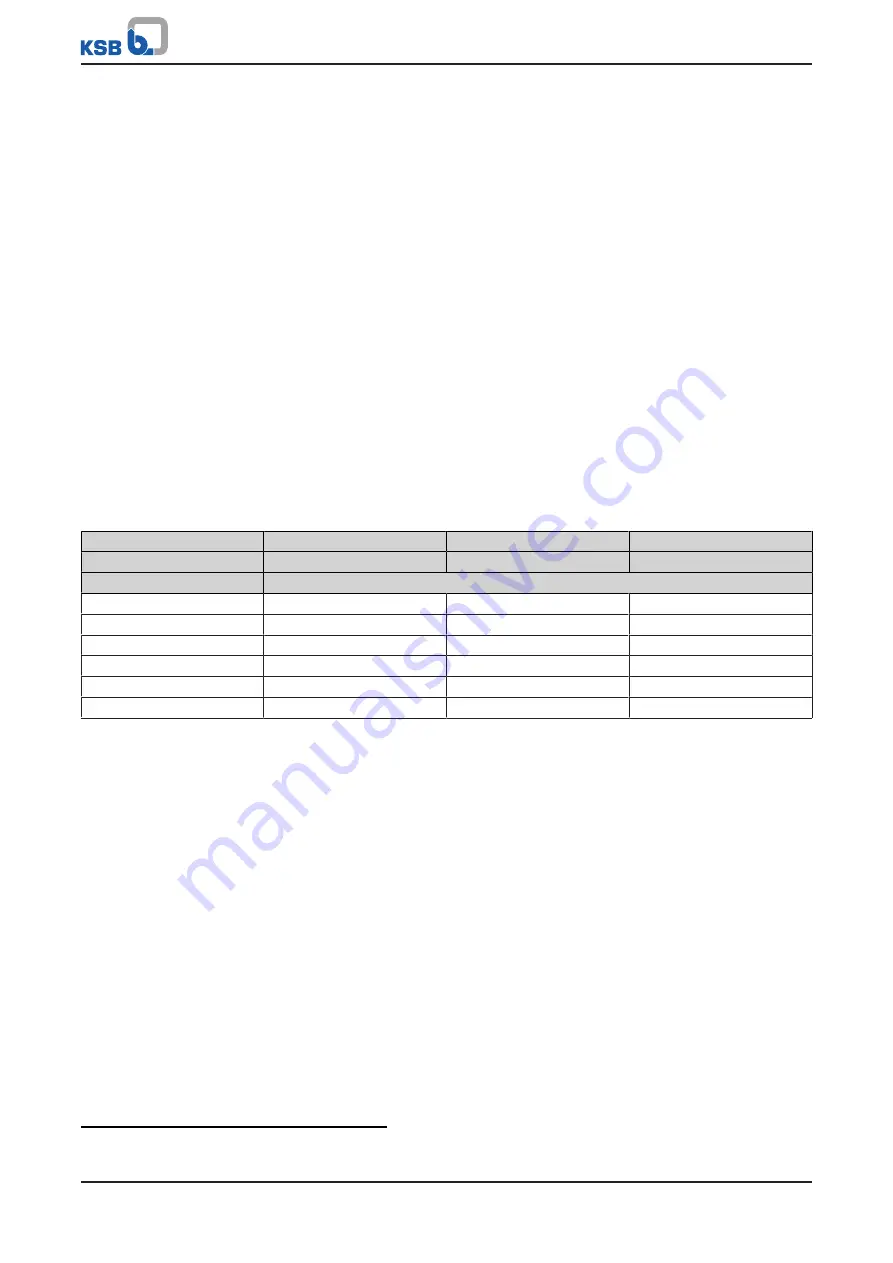

5.5 Tightening torques

Table 6:

Tightening torques for bolted/screwed connections

3)4)

Material

C35E+QT/ C35+N

A4-70/ A4-70

8.8 A2A/ 08

Stamp mark

YK/ Y

A4-70/ A4-70

8.8 / 8

Thread

Tightening torques [Nm]

M8

-

16

23

M10

-

30

46

M12

40

55

80

M16

100

140

190

M20

190

200

380

M24

330

455

660

3)

For unlubricated bolts/screws at room temperature

4)

After repeated tightening of the threads and in case of good lubrication reduce the values by 15 to 20 %.

Summary of Contents for 4K Series

Page 1: ...KSB Mechanical Seal 4K 4KD For the KWP Type Series Installation Operating Manual ...

Page 30: ......

Page 31: ......