5 Installation/Dismantling

17 of 32

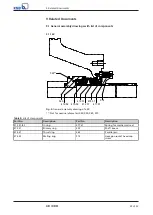

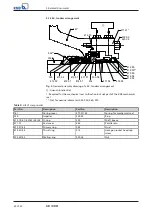

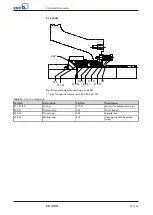

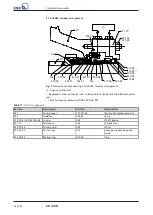

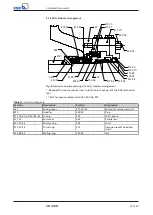

4K / 4KD

G

d

A

K

s

L

Fig. 3:

Checking the installation

A

Required dimension

L

Reference dimension prior to installation

K

Reference dimension after installation

Table 5:

Reference dimension

Bearing bracket

Nominal diameter

G

d

S

A

L

K

[mm] [mm] [mm] [mm] [mm]

P03ax

40

M6

8,5

2

5

36,00 3,5 to 6,5

P04ax

50

M6

8,5

2

5

35,75 3,5 to 6,5

P05ax

60

M6

8,5

2

5

44,75 3,5 to 6,5

P06x

70

M6

8,5

2

5

50,75 3,5 to 6,5

P08sx

80

M10

13

3

7

52,50 5,0 to 9,0

P10ax

100

M10

13

3

7

52,50 5,0 to 9,0

P12sx

120

M10

13

3

7

54,50 5,0 to 9,0

5.4 Removing the mechanical seal

The rules of sound engineering practice and the pump manufacturer's general

provisions apply. Tidiness and cleanliness are essential for proper execution of the

installation work.

For dismantling and reassembly observe the general assembly drawing.

Example of a dismantling sequence for KSB pumps

ü

The operating manual for the pump is on hand.

ü

The mechanical seal is accessible.

ü

The back pull-out unit of the pump has been placed in a clean and level assembly

area.

ü

The pump and/or machinery has been prepared in accordance with the

manufacturer's instructions for dismantling the mechanical seal.

1.

Pull shaft sleeve 523 with mating ring 475.52 and O-ring 412.52 off the shaft

using an extractor in the removal groove in shaft sleeve 523.

2.

Pull mating ring 475.52 out of shaft sleeve 523.

3.

Undo the hexagon head bolts. Remove casing cover 161 with the joint ring as

well as primary ring 472.51 with secondary seal 412.51 and spring arrangement

from the bearing bracket lantern.

4.

Press primary ring 472.51 with secondary seal 412.51 out of casing cover 161.

5.

Undo hexagon socket head cap screws 914 with springs 477.51 and thrust ring

474.51.

Summary of Contents for 4K Series

Page 1: ...KSB Mechanical Seal 4K 4KD For the KWP Type Series Installation Operating Manual ...

Page 30: ......

Page 31: ......