FCU 500, FCU 505 · Edition 02.17

10

Application

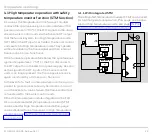

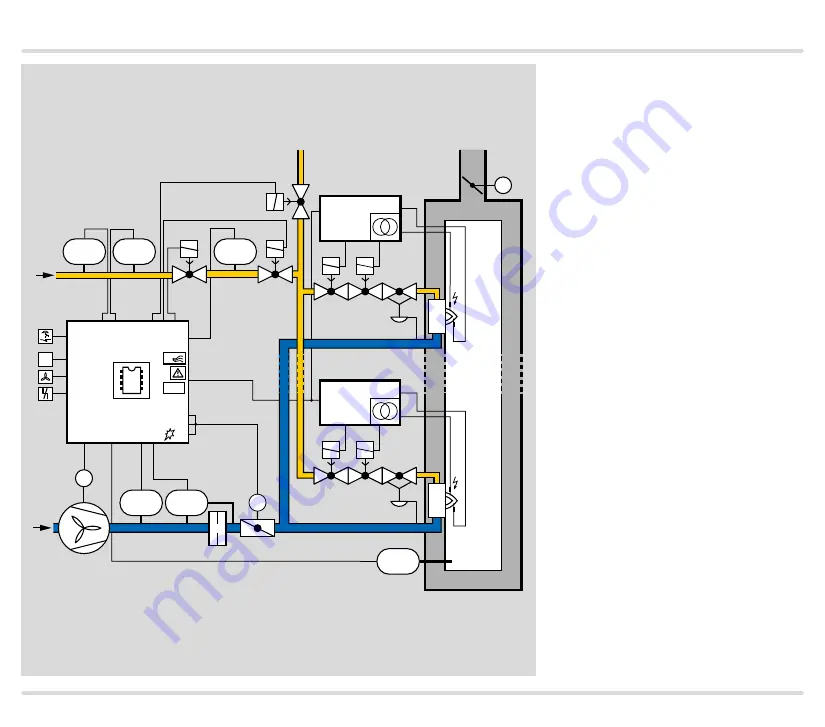

1 .1 .2 Modulating burner control

For processes that do not require

heavy circulation in the furnace, e.g.

aluminium smelting furnaces.

This system is suitable for process-

es in which infiltrated air may flow

into the furnace through switched

off burners. The capacity can be

adjusted continuously by activating

the air control valve (analogue or

3-point step signal). The pneumatic

ratio control system controls the

gas pressure proportionally to the

air pressure and thus maintains a

constant air/gas ratio. At the same

time, it acts as a low air pressure

protection device.

One burner control unit per burner

is required for ignition and monitor-

ing.

The centrally checked safety func-

tions such as pre-purge, setting the

valve to ignition position via a but-

terfly valve control system, tight-

ness test, flow detector and pres-

sure switch check (gas

min.

, gas

max.

,

air

min.

) are provided by the FCU 500.

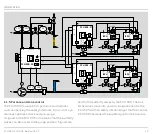

FCU 500..F1

µC

P

DG

DG

DG

VAS

VAS

VCG

VCG

DG

min

DG

max

49

15

13

14

50

53

45

47 48

58

p

u

/2

M

PZL

PZH

PZ

PZL

PDZ

TE

BCU 460..L

BCU 460..L

M

M

TC

90°

➔

0°

0°

➔

90°

54

55

VAS

DG

DG

>750°

ϑ

1

2

3

DL

min

DL

Purge

46

STM