GB-3

D

GB

F

NL

I

E

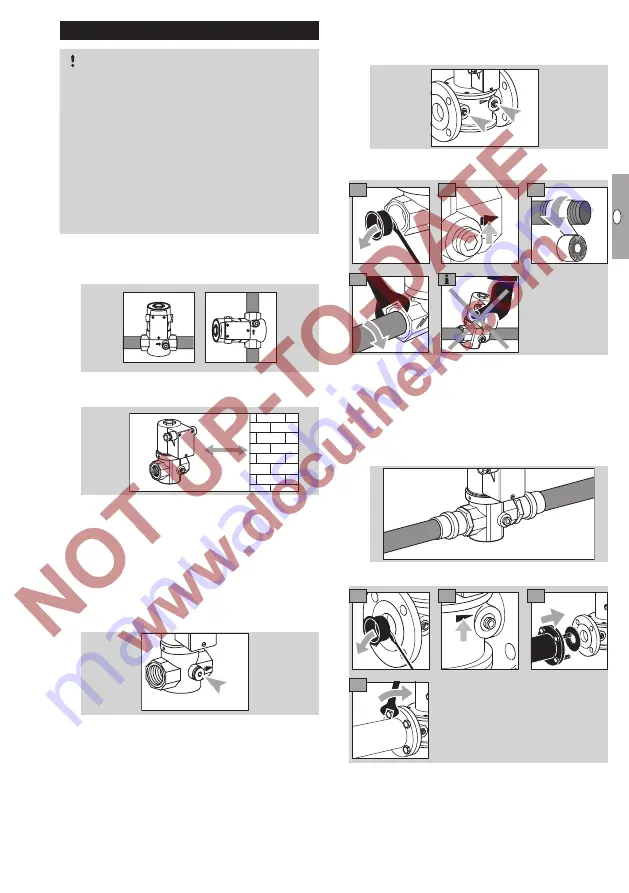

Installation

CAUTION

Please observe the following to ensure that the VG

is not damaged during installation and operation:

–

Do not clamp the unit in a vice. Only secure the

flange by holding the octagon with a suitable

spanner. Risk of external leakage

.

– Continuous operation at high temperatures

accelerates the ageing of elastomer materials.

–

Do not install or store the unit in the open air.

–

Check max. ambient temperature – see type

label.

–

Check max. inlet pressure – see type label.

▷

Installation position: black solenoid actuator in

the vertical upright position or tilted up to the

horizontal, not upside down.

> 20 mm

▷

The housing must not be in contact with masonry.

Minimum clearance 20 mm (0.79").

> 20 mm

▷

Sealing material and dirt, e.g. thread cuttings,

must not be allowed to get into the valve housing.

▷

Install a filter upstream of every system.

▷

Use approved sealing material only.

▷

Use a suitable spanner.

▷

Ensure that there is sufficient space for installa-

tion and adjustment.

▷

On VG 10/15 – 40/32, the inlet pressure p

u

can

be measured at the pressure test point.

p

u

p

u

p

d

▷

On VG 40 – 65, the inlet pressure p

u

and the

outlet pressure p

d

can be measured at the re-

spective pressure test point.

p

u

p

u

p

d

VG..R

2

3

1

4

Gas compression fittings

▷

The seals in some gas compression fittings

are approved for temperatures of up to 70°C

(158°F). This temperature limit will not be ex-

ceeded if the flow through the pipe is at least

1 m

3

/h (35.31 SCFH) of gas and the maximum

ambient temperature is 50°C (122°F).

VG..F

2

3

1

3