GB-2

D

GB

F

NL

I

E

Checking the usage

TC 410 for tightness test before every controlled start-

up or after every controlled shut-down in systems

with 2 safety valves. Tightness control TC 410 can

be used for individual valves, quick opening or slow

opening with start gas rate. The valves are controlled

directly for testing by the TC 410. A pressure switch

for gas must be mounted on the interspace between

the valves to be monitored for the tightness test.

This function is only guaranteed when used within the

specified limits – see page 5 (Technical data). Any

other use is considered as non-compliant.

Type code

Code

Description

TC

Tightness control

4

In control cabinet

Testing before or after burner run

0

External pressure switch required

T

T-product

-

-0

Test period: 10 to 60 s

Test period: 100 to 600 s

K

N

T

Mains voltage: 24 V DC

110/120 V AC, 50/60 Hz

220/240 V AC, 50/60 Hz

Part designations

OK

TEST

1

2

1

2

Upper housing section

Lower housing section

Type label

▷

Test period and gas type, mains voltage, power

consumption, ambient temperature, enclosure,

switching current and maximum inlet pressure –

see type label.

D-49018 Osnabrück, Germany

TEST OK

1

2

CE 0085AP0020

TC 410

Imax 5A

IP40

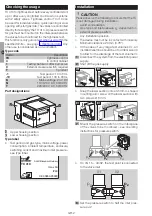

Installation

CAUTION

Please observe the following to ensure that the TC

is not damaged during installation:

– Avoid condensation.

– Gas type and inlet pressure p

u

: dependent on

external pressure switch.

▷

Any installation position.

▷

The device must not be in contact with masonry.

Minimum clearance 20 mm (0.78").

▷

In the case of very large test volumes V

P

, an

installed relief line should be of nominal size 40

to allow for the discharge of the test volume V

P

.

Disconnect the system from the electrical power

supply.

Shut off the gas supply.

OK

TEST

1

2

1

2

70 (2.76")

21 (0.83")

37,5 (1.48"

)

ø 5 (ø 0.2")

4

3

5

6

6

▷

Snap the lower section onto a 35 mm U-shaped

mounting rail or screw on the lower section with

two screws Ø 5 mm.

OK

TEST

1

2

1

2

70 (2.76")

21 (0.83")

37,5 (1.48"

)

ø 5 (ø 0.2")

4

3

5

6

6

7

Mount the pressure switch on the interspace

of the valves to be monitored – see operating

instructions for pressure switch.

p

u

p

d

p

z

▷

On VG 15 – 40/32, the test point is connected

to the valve inlet.

V1

V2

p

u

p

z

8

Set the pressure switch to half the inlet pres-

sure p

u

/2.