7

General rules

Range of application

Use machines for cleaning tasks with high-pressure water jet and detergents or with

high-pressure water jet without detergents only.

Inspections

The machine must be inspected according to the “Guidelines for Liquid Spray Devices”

at least once every 12 months by a qualified person, to ensure that continued safe

operation is guaranteed. The results of the inspection are to be recorded in writing. This

may be done in any form. For inspection reports see pages 49 - 51.

High-pressure cleaners used for commercial purposes have

to be checked by a qualified person at least every 12 months!

Accident prevention

The machine is designed for accidents to be impossible if used correctly. The operator is

to be notified of the risk of injury from hot machine parts and the high pressure water jet.

The “Guidelines for Liquid Spray Devices” must be complied with (see pages 8 and 9).

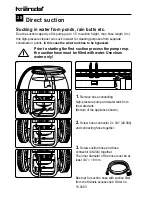

Oil change:

Oil leakage: If oil leaks out, contact nearest customer ser-

vice (dealer) immediately. (Environmental damages, trans-

mission damages, loss of guarantee). In case of increased

humidity or fluctuations in temperature the formation of

condensed water is possible; if the oil turns grey, it has to

be changed immediately.

Oil drain screw

(View of appliance from below)

The first oil change should be carried out

after approximately

50 operating hours

,

then every year or after 1000 operating

hours. Open the oil drain screw at the bot-

tom of the device over a collection rese-

voir. The oil is to be caught in the reservoir

and disposed of in an approved manner.

New oil: 1,0 l - Motor oil

10/W-60 SAE semi-synthetic oil

Summary of Contents for quadro 1500 TS

Page 32: ...Spare parts list quadro 1500 TS TST Complete assembly 32...

Page 36: ...Spare parts list Kr nzle quadro 1500 TS TST Pump motor 36...

Page 38: ...Spare parts list Kr nzle quadro 1500 TS TST Pump transmission unit for AQ pump 38...

Page 40: ...Spare parts list Kr nzle quadro 1500 TS TST Unloader valve and pressure switch 40...

Page 44: ...Spare parts list Kr nzle quadro 1500 TS TST Hose drum 44...