CHECK, MAINTAIN, CLEAN

- Always carry out maintenance work under unloaded condition.

- Watch out for possible hazards during maintenance work (bumping, falling down).

- Use a slightly damp cloth and a non-abrasive cleaning agent for cleaning.

TECHNICAL DATA / SPECIFICATIONS

Material

Tubes, angle: steel, powder-coated black

Screws, washers, threads: galvanised steel

Plastic parts: PA, PE, TPE black

Dimensions

Threaded connection: 3/8" and 5/8"

Arm: 240-400 mm - 160 mm adjustment range

Height: 268-418 mm - 150 mm adjustment range

Weight

1.61

Cardboard

inside: 380 x 136 x 57 mm

KÖNIG & MEYER

GmbH & Co. KG

Kiesweg 2, 97877 Wertheim, www.k-m.de

18807-000-55 Rev.07 03-80-379-00 7/20

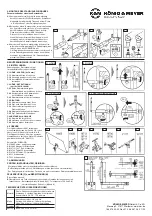

4. MOUNTING THE STAND/EXTENSION TUBE

Assembly of the individual components

4.1

Boom arm and adjustable tube cpl.

b

are already

4.1

pre-assembled ex-factory. The removal of the

4.1

screw

b.1

enables the separation of both tubes,

4.1

e.g. for maintenance or cleaning purposes.

4.2

Insert bolts of the stand/extension tube

a

into

4.2

the holder of the adjustable tube

b

and secure

4.2

connection by screwing the set screw

f

.

4.2

Use Allen key SW3

i

for this purpose.

4.2

The set screw has to be screwed in the stand/

4.2

extension tube until you can still turn the set

4.2

screw but not remove it. Subsequently tighten

4.2

the clamping screw

e

.

4.3

At the upper end of the extension tube you will find

4.3

a.2

an ex-factory mounted 5/8" reduction thread.

4.3

However, if the ACCESSORIES

6

are furnished

4.3

with 3/8" threaded bushes, remove the above-

4.3

mentioned reduction thread and use the 3/8"

4.3

threaded bolt together with the thumb wheel that is

4.3

firmly connected to the standtube.

USER INSTRUCTIONS / FUNCTIONS

5. SETTINGS

Undertake setting(s) changes if necessary,

under unloaded condition.

5.1 HEIGHT - EXTRACTION (0-150 mm)

5.1.1

Slightly loosen clamping nut

a.1

.

5.1.2

Slide the pull-out to the desired position.

5.1.3

Then retighten the clamping nut.

5.2 HEIGHT - FASTENING

5.2

(only for 18810, 18820)

5.2.1

Loosen both clamping nuts

g

of

5.2.1

the clamping angle with slots

c

.

5.2.2

Position boom/adjustment

b

and

5.2.2

clamping angle with slots

c

.

5.2.3

Tighten the clamping nuts again.

5.3 DIRECTION

5.3.1

Loosen clamping screw

e

slightly.

5.3.2

If necessary, also loosen set screw

f

.

5.3.3

Turn the universal holder in chosen

5.3.3

direction.

5.3.4

Retighten the clamping screw.

5.3.5

If necessary, tighten set screw

f

.

5.4 DISTANCE of LOADING

5.4.1

Slightly loosen clamp

b.1

.

5.4.2

Move the holder as required.

5.4.3

Tighten the clamp again.

6. ACCESSORIES

The universal holder 18807 has a threaded

bolt size 3/8" and 5/8" adapter (see

a.2

/

4.3

).

The counterpart must be connected via a

suitable threaded bushing. If necessary, use a

thread adapter (e.g. K&M 215).

Examples of ACCESSORIES:

6.1

18805 Sheet music and concept holder

6.2

19685 Adapter for screens

6.3

19712/14/17 iPad stand holder

6.4

19742 Tablet PC stand holder

6.5

19790/95 Tablet PC stand holder

6.6

211 Boom arm

6.7

223 Gooseneck

7. DIMENSIONS

FAULT-FINDING (F) and REPAIR (R)

F

Installation wobbles.

R

Check if the parts are correctly arranged and the threads are tightened.

R

:

In particular: - Mounting bracket (

3.4

and

3.11

) - Telescopic tubes (

5.1

and

5.4

)

R

:In particular:

- Screw connections of accessories (

4.3

and

6

)

4.1

6.1

6.2

6.3

7

6.4

6.5

6.6

6.7

5.3 DIRECTION

5.4 DISTANCE of LOADING

5.1 HEIGHT

5.2 HEIGHT

4.2

4.3