1-13

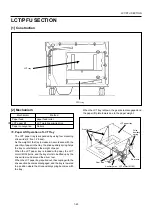

[5] Paper Exit Gate Control

SD103

103-1

103-2

24V DC

SD103 DRIVE

CB

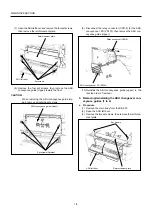

The paper exit gate is driven by SD103 (ADU gate solenoid).

The SD103 is controlled by the CB (control board) of the main

body.

1. Operation

a. Changing the paper exit gate

The paper exit guide is raised by SD103 (ADU gate sole-

noid) to feed the paper to the ADU when PS8 (paper exit PS)

is ON during the face side copying.

The paper exit guide is lowered due to OFF of SD103 when

the face side copying has been completed. The paper is

delivered to the exist tray after copying the back side.

2. Signal

a. Output signal

(1) SD103DRIVE (CB

→

SD103)

This is the ON/OFF signal for SD103.

[L] : SD103 ON (paper exit gate up)

[H] : SD103 OFF(paper exit gate down)

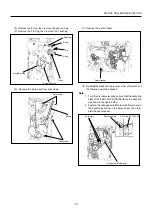

[6] Paper Feed Control

SD104

217-1

217-2

215-A1

215-A2

24V DC

SD104 DRIVE

24V DC

SD105 DRIVE

ADU DB

SD105

CB

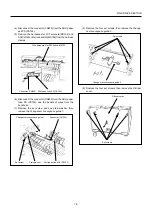

Paper is fed from the LCT or PFU by transmitting the drive force

from M1 (main motor) to the paper feed roller using SD104 (LCT

solenoid) or SD105 (PFU paper feed solenoid). SD104 and

SD105 are controlled by the CB (control board) through ADUDB

(ADU drive board).

1. Operation

SD104 or SD105 is turned ON for specified period to feed

paper from the tray when the copy button is pressed. Paper

feed for the 2nd and after will start at a specified interval

from the previous paper feed ON.

2. Signal

a. Output signal

(1) SD104DRIVE (CB

→

SD104)

This is the ON/OFF signal for SD104.

[L] : SD104 ON

[H] : SD104 OFF

(2) SD105DRIVE (CB

→

SD105)

This is the ON/OFF signal for SD105.

[L] : SD105 ON

[H] : SD105 OFF

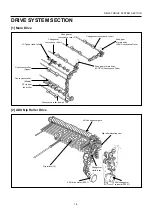

MAIN DRIVE SECTION