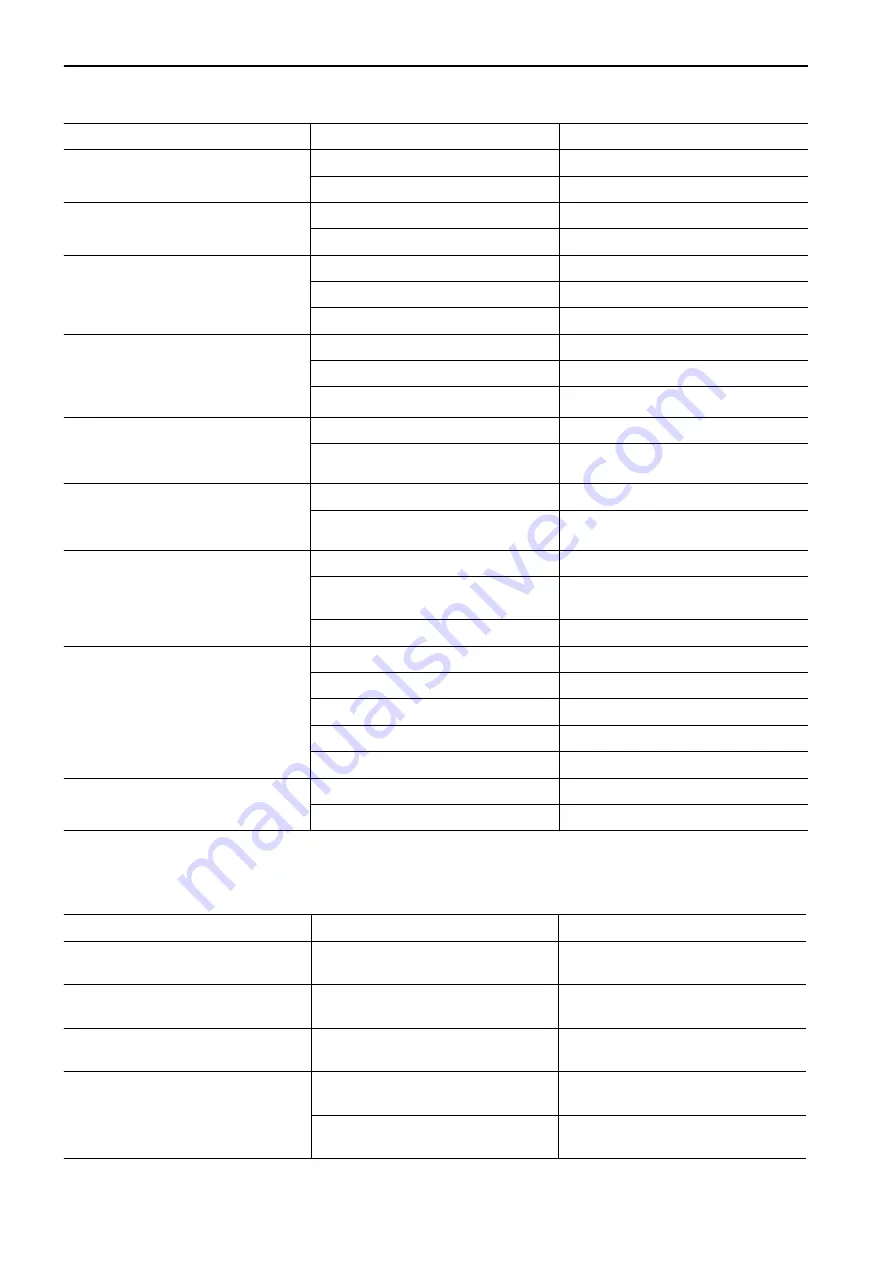

Problem

Main causes

Remedy

Starting motor turns engine sluggish-

ly.

Insufficient battery charge

Charge battery.

Defective starting motor

Replace. (*)

Starting motor disengages before en-

gine starts.

Defective wiring

Check, repair. (*)

Insufficient battery charge

Charge battery.

Automatic preheating does not work. Defective wiring

Check, repair. (*)

Defective heater relay

Replace. (*)

Defective engine controller

Check, replace (*)

Preheating pilot lamp does not light

up.

(when coolant temperature is -5 °C or

below)

Defective wiring

Check, repair. (*)

Defective heater relay

Replace. (*)

Defective monitor

Replace. (*)

Oil pressure caution lamp does not

light up when engine is stopped.

(starting switch is at ON position)

Defective monitor

Replace. (*)

Defective caution lamp switch

Replace. (*)

Charge level caution lamp does not

light up when engine is stopped.

(starting switch is at ON position)

Defective monitor

Replace. (*)

Defective wiring

Check, repair. (*)

Outside of electrical intake air heater

is not warm when touched with hand.

Defective wiring

Check, repair. (*)

Wire breakage in electrical intake air

heater

Replace. (*)

Defective operation of heater relay

Check, repair heater relay. (*)

Defective operation of air conditioner Fuse blow

Check, repair. (*)

Insufficient battery charge

Charge battery.

Defective air conditioner switch

Replace air conditioner switch. (*)

Defective blower switch

Replace blower switch. (*)

Defective compressor

Replace. (*)

Engine does not start.

(“L04” lights up on monitor.)

Damaged data in the controller

Check, repair. (*)

Other system troubles

Check, repair. (*)

PHENOMENA AND ACTIONS FOR CHASSIS

• For the remedies indicated with (*) in the remedy column, always contact your Komatsu distributor.

• In cases of problems or causes which are not listed below, ask your Komatsu distributor for repairs.

Problem

Main causes

Remedy

When brake pedal is depressed, ma-

chine does not stop.

Brakes out of adjustment, defective

oil pressure

Adjust, check, repair. (*)

Track shoe comes off.

Track tension is too low.

Adjust track tension, see WHEN RE-

QUIRED.

Abnormal wear of sprocket

Track shoe is too low, or too high.

Adjust track tension, see WHEN RE-

QUIRED.

Blade and ripper rise slowly or do not

rise.

Insufficient hydraulic oil level

Set oil to specified level. See

CHECKS BEFORE STARTING.

Work equipment lock lever is in

LOCK.

Set to FREE.

TROUBLES AND ACTIONS

OPERATION

3-246

Summary of Contents for D155AX-8E0

Page 2: ......

Page 11: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVELS 1 9...

Page 24: ......

Page 312: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 404: ......

Page 405: ...REPLACEMENT PARTS 7 1...