Reviews:

No comments

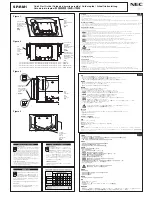

Related manuals for DM - 602/604

MultiSync X431BT

Brand: NEC Pages: 3

MultiSync X461UNV

Brand: NEC Pages: 42

MultiSync P701

Brand: NEC Pages: 2

MultiSync P701

Brand: NEC Pages: 2

50XR5

Brand: NEC Pages: 20

60XM5 - PlasmaSync - 60" Plasma Panel

Brand: NEC Pages: 48

MultiSync LCD4020

Brand: NEC Pages: 2

XC 300

Brand: LifeSource Pages: 13

TW191D

Brand: I-Inc Pages: 19

ELI70-CP

Brand: FDI Pages: 14

LM520i

Brand: AOC Pages: 40

CMG Series

Brand: Azbil Pages: 34

KIOSK 2 Series

Brand: AIRxTOUCH Pages: 22

Alpha pH 550

Brand: EUTECH INSTRUMENTS Pages: 44

VT213C

Brand: VarTech Systems Pages: 18

RD-232

Brand: Rice Lake Pages: 24

710C

Brand: Daewoo Pages: 54

iHAP-1700

Brand: I-Tech Pages: 28