Servicing

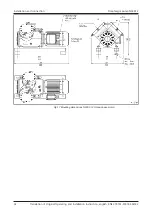

Diaphragm pump N630.12

40

Translation of Original Operating and Installation Instruction, english, KNF 318761-318764 02/22

8.2 Cleaning

8.2.1 Flushing the pump

When transferring dangerous and environmentally hazardous media, KNF

recommends flushing the pump with air at atmospheric pressure for a few

minutes prior to switch-off (if necessary for safety reasons: with an inert

gas) to extend the service life of the diaphragm.

à

Discharge the media safely.

8.2.2 Cleaning the pump

CAUTION

Risk of burns from hot pump parts

The pump head or motor may still be hot after op-

eration of the pump.

à

Allow the pump to cool after operation.

WARNING

Health hazard due to dangerous substances in the

pump

Depending on the medium being transferred,

caustic burns or poisoning is possible.

à

Wear protective equipment if necessary, e.g.,

protective gloves, goggles.

à

Clean the pump with suitable measures.

NOTICE

During cleaning work, ensure that no fluids enter

the interior of the housing.

à

Only clean the pump with a dry wiping cloth. When cleaning, use no

solvents if possible as these can affect the plastic parts.

à

Only use solvents during cleaning if head materials are not affected

(ensure resistance of the material).

à

If compressed air is present, blow out the components.

Summary of Contents for N630.12

Page 65: ...13...

Page 67: ...15 9 Documents provided Circuit diagram...

Page 69: ......

Page 82: ...13...

Page 84: ...15 9 Documents provided Circuit diagram...

Page 87: ......

Page 88: ...KNF worldwide You can find our local KNF partners at www knf com...