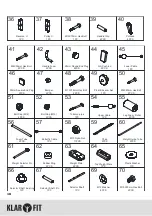

27

Step 6

1. Assembly of the upper cable (54)

a. With the upper cable (54) in groove of pulley (27), thread the upper cable (54)

through the upper cross beam (8).

b. Install pulley no.1 (27) And two pulley bushings (32) to the upper cross beam (8),

using one M10x65mm hex bolt (24), two M10 washers (35) and one M10 nylon nut

(58).

c. Install pulley no.2 (27) And two pulley bushings (32) to the upper cross beam (8),

using one M10x65mm hex bolt (24), two M10 washers (35) and one M10 nylon nut

(58).

d. Install pulley no.4 (27) To the upper cross beam (8), using one M10x45mm hex bolt

(25), two M10 washers (35) and one M10 nylon nut (58).

e. Attach the bolt end of upper cable (54) to the selector shaft (68) with a plastic

washer (65).

f. Install pulley no.3 (27) To the pulley u (37), using one 10x45mm hex bolt (25), two

M10 washers (35) and one M10 nylon nut (58).

g. Attach the lat bar (9) to the other end of upper cable (54) using one pothook (40).

2.

Assemble the butterfly cable (57)

a.

Attach both ends of butterfly cable (57) to the left and right butterfly arm (6&7),

using two M10x35mm hex bolts (70), two M10 nuts (10), four M10 washers (35)

and two M10 nylon nuts (58).

b.

Install pulley no.5&7 (27) To the pulley bracket (26), using two M10x45 mm hex

bolts (25), four M10 washers (35) and two M10 nylon nuts (58).

c. Install pulley no.6 (27) To the reverse u (36), using one M10x45mm hex bolt (25),

two M10 washers (35) and one M10 nylon nut (58).

3. Assembly the lower cable (45)

a. With the lower cable (45) in groove of pulley (27) through the leg extension tube

(11).

b. Install pulley no.8 (27) And two pulley bushings (32) to the leg extension tube (11),

using one M10x65mm hex bolt (24), two M10 washers (35) and one M10 nylon nut

(58).

c. Install pulley no.9 (27) And two pulley bushings (32) to the main support tube (4),

using one M10x65mm hex bolt (24), two M10 washers (35) and one M10 nylon nut

(58).

d. Install pulley no.10 (27) To the reverse u (36), using one M10x45mm hex bolt (25),

two M10 washers (35) and one M10 nylon nut (58).

e. Install pulley no.11 (27) To the main base tube (1), using one M10x45mm hex bolt

(25), two M10 washers (35) and one M10 nylon nut (58).

f. Install pulley no.12 (27) To the pulley u (37), using one M10x45mm hex bolt (25),

two M10 washers (35) and one M10 nylon nut (58).

g. Attach the end of lower cable (45) to the main base tube (1), using one M8x40mm

hex bolt (50), two M8 washers (19), one M8 nylon nut (20), one pothook (40) and

one chain (59).

h. Attach the lower bar (13) to the other end of lower cable (45), using two pothooks

(40) and one chain (59).

Summary of Contents for 10031408

Page 1: ...10031408 Strongbase...

Page 12: ...12 1 2 3 4 8 9 10 11 12 6 5 7 54 57 45...

Page 15: ...10031408 Strongbase...