2-12

GAS HOOKUP & LEAK CHECK

1.

For Natural Gas:

Connect a certified 1/2

″

gas supply pipe to the inlet side of the

regulator from a natural gas supply, ac-

cording to local codes requirements. Use

a pipe thread sealant that is certified for

use with natural gas at connections, where

required.

2.

For L.P. Gas:

Connect the regulator hose

connector to a full 20# L.P. tank, and

hand-tighten it.

3.

Turn on the gas supply to the grill.

4.

Test all of the connections by brushing on

an approved noncorrosive leak-detection

solution. Bubbles will indicate a leak. Cor-

rect any leaks found.

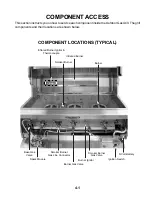

ADJUSTING THE AIR SHUTTERS

1.

Light the grill using information in “Lighting

The Grill” on page 3-3.

2.

Observe the flame to determine which

burners need adjustment, and how the

flame is acting.

3.

Turn off the valve and wait until the grill

and burners are cool.

4.

Remove the grill grates and sear plates.

5.

Remove the burner and loosen the air

shutter adjustment screw.

a) If the flame is yellow (not enough air),

turn the air shutter counterclockwise.

b) If the flame is noisy, or lifts away from

the burner (too much air), turn the air

shutter clockwise.

Adjustment should be from 1/8

″

to 1/4

″

.

6.

Tighten the air shutter adjustment screw.

Air Shutter Screw

7.

Replace the burner sear plates and grates.

8.

Ignite the burners and check the flames.

9.

Repeat Steps 1 through 8, if needed. Only

adjust the burners that need adjustment.

LOW FLAME ADJUSTMENT

If the flame goes out on the “LO” setting, the low

flame setting must be adjusted.

1.

Turn off the valve and wait until the grill

and burners are cool.

2.

Remove the grill grates and sear plates.

3.

Light the grill using the information in “Light-

ing The Grill” on page 3-3.

4.

Turn the burner to its lowest setting and

remove the knob.

5.

Hold the valve stem with pliers and insert

a thin flat-blade screwdriver into the shaft.

6.

Watch the flame and slowly turn the screw-

driver counterclockwise.

7.

Adjust the flame to a minimum stable

flame.

8.

Replace the control knob and turn off the

burner.

9.

Repeat Steps 3 through 8 for each burner,

if needed.

10. Replace the sear plates and grates after

the burners have cooled.

Valve Stem