Chapter 5. Inputs and Outputs

5-1

Chapter 5. Inputs and Outputs

Introduction

The

I/O

Menu is used to enter parameters for

setpoints, current output (4-20 mA, 0-20 mA),

serial port configuration, printer functions, and

PLC interface. This chapter covers the

functions in the

I/O

Menu. Explanations of

each of the functions are provided. Addition-

ally, detailed navigation procedures through

the menu tree are provided for the setpoint

and current output functions.

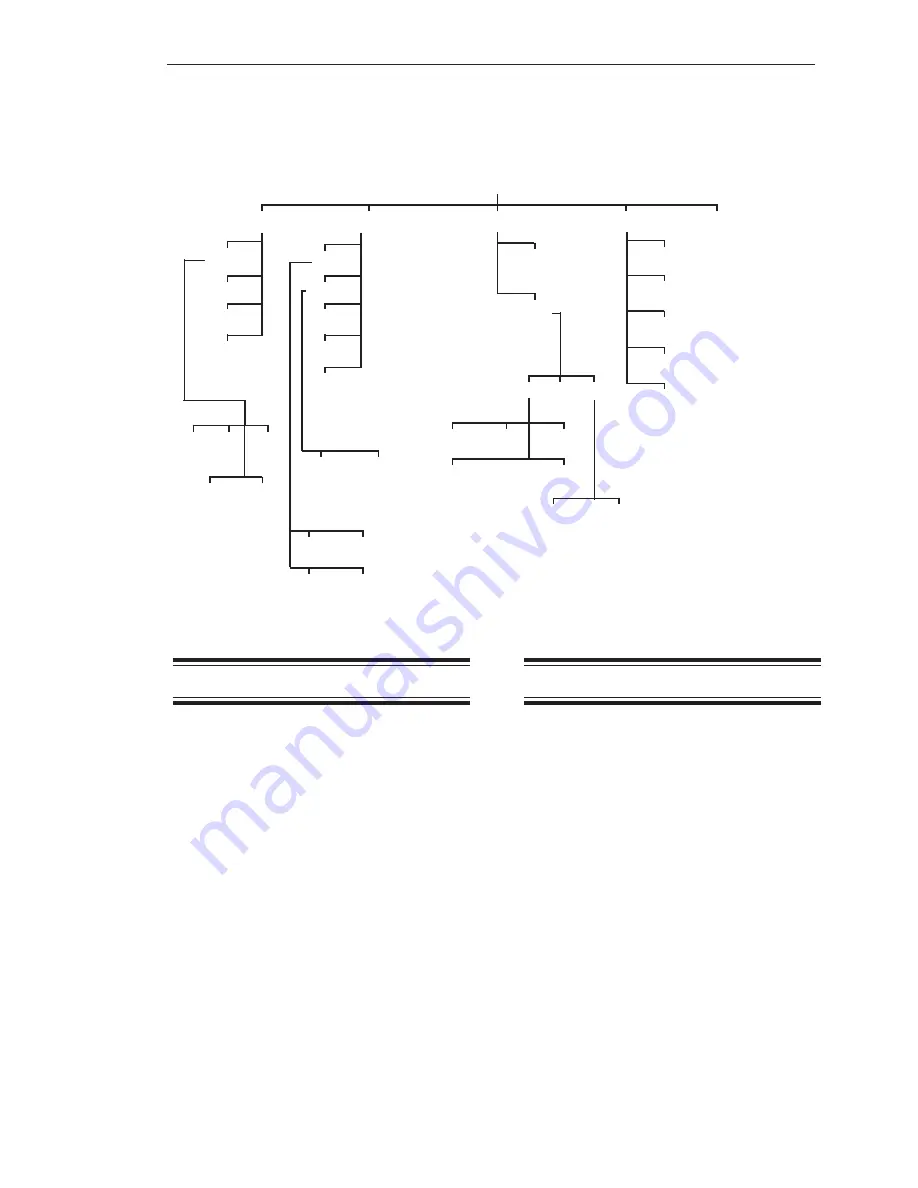

As shown in Figure 5-1, the

I/O

Menu has five

submenus:

1.

Setpt

— used to set up setpoints to

activate or deactivate a relay

2.

Iout

— used to set up current outputs

3.

Serl

— used to set up serial communica-

tions settings for use with a PLC,

printer, etc.

4.

Prnt

— used to direct output to a printer

5.

PLC

— used to set up communications

with a PLC

SetPt

The setpoint value is the weight measurement

in a vessel where you wish a device (for

example, a pump) to activate or deactivate.

The setpoint setup functions for each vessel

are accessed in this menu. They include

adding and deleting setpoints and selecting

activation levels, high or low activation,

deadband values, fail-safe parameters, and

net or gross weight.

The

Descriptions

section defines each of the

parameters. The

Setting Up the Setpoint

and

Setpoint Report

sections provide the detailed

procedures for using the Weigh II.

Descriptions

Set

This menu is used to select the setpoint to

be set up for the displayed vessel. Depending

on the options you selected for your Weigh II,

up to eight setpoints can be assigned per

Figure 5-1. The Input/Output Menu Tree

Tare

GO1

GO_ALL

Timed

PDly

Setpt

Iout

Serl

Prnt

PLC

Set

Report

Delete

Add

Set

Mode

Rprt

Delete

Add

HideS

Set

Val

I/O

Net/Grs

Fsafe

Hi/Lo

0-20ma

4/0ma

20ma

Net/Grs

Baud Addr Mode

Printer

Slave

4-20ma

Dead

1200

2400

4800

9600

19200

Fsafe

Summary of Contents for Weigh II

Page 12: ...2 4 Chapter 2 Hardware Installation...

Page 20: ...3 8 Chapter 3 Menu Tree Keyboard Functions and Quick Start...

Page 50: ...6 12 Chapter 6 Calibration...

Page 68: ...A 2 Appendix A Product Specifications...

Page 70: ...B 2 Appendix B Summary of Commands Used When Vessel Mounting Hot Keys...

Page 77: ...Appendix E E 1 This appendix not used at this time...

Page 78: ...Appendix E E 2...

Page 80: ...Appendix F Technical Drawings F 2...

Page 81: ...Appendix F Technical Drawings F 3...

Page 82: ...Appendix F Technical Drawings F 4...

Page 83: ...Appendix F Technical Drawings F 5...

Page 84: ...Appendix F Technical Drawings F 6...

Page 85: ...Appendix F Technical Drawings F 7...

Page 86: ...Appendix F Technical Drawings F 8...

Page 87: ...Appendix F Technical Drawings F 9...

Page 88: ...Appendix F Technical Drawings F 10...

Page 89: ...Appendix F Technical Drawings F 11...

Page 90: ...Appendix F Technical Drawings F 12...

Page 91: ...Appendix F Technical Drawings F 13...

Page 92: ...Appendix F Technical Drawings F 14...

Page 93: ...Appendix F Technical Drawings F 15...

Page 94: ...Appendix F Technical Drawings F 16...

Page 95: ...Appendix F Technical Drawings F 17...

Page 96: ...Appendix F Technical Drawings F 18...

Page 97: ...Appendix F Technical Drawings F 19...

Page 98: ...Appendix F Technical Drawings F 20...

Page 99: ...Appendix F Technical Drawings F 21...

Page 100: ...Appendix F Technical Drawings F 22...

Page 101: ...Appendix F Technical Drawings F 23...

Page 102: ...Appendix F Technical Drawings F 24...

Page 103: ...Appendix F Technical Drawings F 25...

Page 104: ...Appendix F Technical Drawings F 26...

Page 105: ...Appendix F Technical Drawings F 27...

Page 106: ...Appendix F Technical Drawings F 28...

Page 107: ...Appendix F Technical Drawings F 29...

Page 108: ...Appendix F Technical Drawings F 30...

Page 109: ...Appendix F Technical Drawings F 31...

Page 110: ...Appendix F Technical Drawings F 32...

Page 116: ...Appendix G Calculation of Maunal Calibration Parameters G 6...